Diamond ring wheels

for the electronics industry

Diamond grinding tools for machining wafers (silicon) in the microchip industry. For an optimum result we recommend grinding tools with diamond in resin and vitrified bonding systems.

- Cool polished section

- Good surface finishes

| Downloads |

|---|

| Image flyer PDF 817 kb |

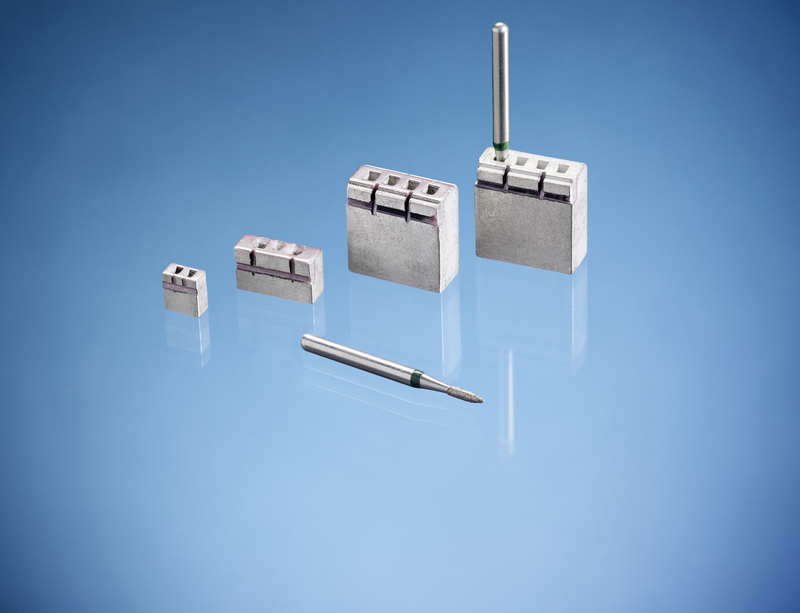

Diamond mounted points

for electronic components

Grinding tools exclusively with diamond in electroplated bond systems.

- High dimensional accuracy

| Downloads |

|---|

| Image flyer PDF 817 kb |

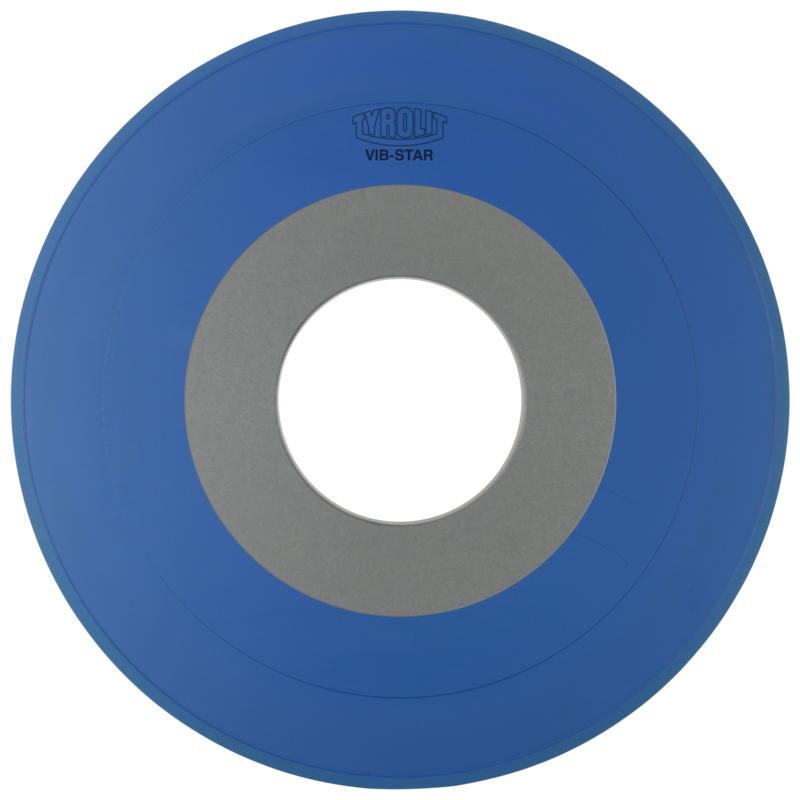

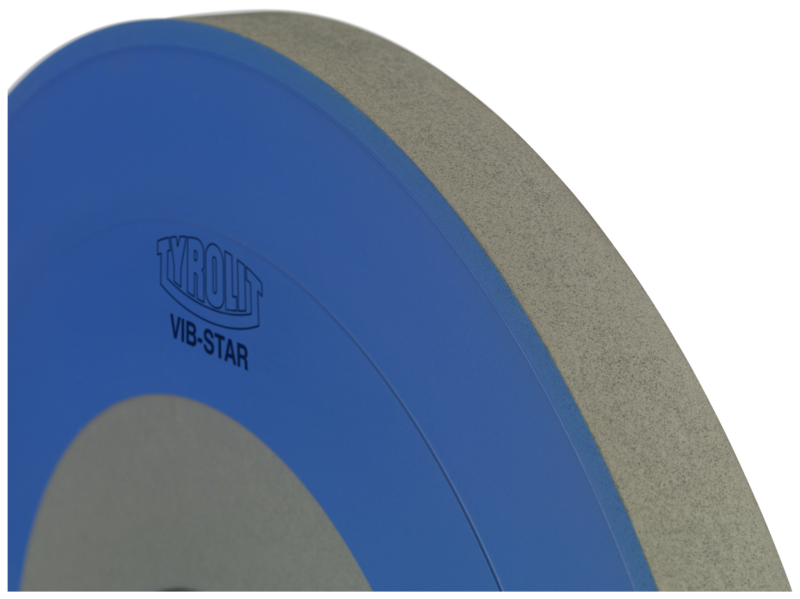

DIAMANT + VIB Star TK

Diamond grinding tools with VIB-Star core for technical ceramic components

Diamond grinding tools with cushioning plastic core system for machining very hard materials and technical ceramic components. Straight diamond grinding tools in vitrified bond for the machining of ceramic components require special damping, thus VIBSTAR is only available in certain dimensions on request.

- Damping + low weight

- Better surface finishes

- Longer lifetime

- Improved grinding ratio

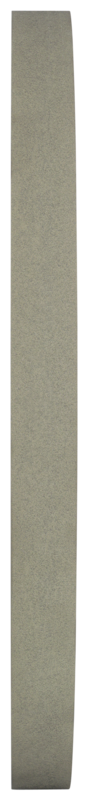

ELASTIC

Elastic for the watchmaking industry

Elastic-bonded grinding and polishing tools for the machining of precision components. These are mainly used for precision mechanics in the watchmaking, spectacle and jewellery industries. Our ELASTIC grinding tools were adapted for diverse applications and are used in the deburring, effect grinding, fine grinding and polishing of precision components.

- Adaptable (elastic)

- Wet and dry grinding

- Large range of grit sizes

- Bond versions

| Downloads |

|---|

| Image flyer PDF 2.40 mb |

Elastic grinding tools for the machining of implants/prostheses

Flexible elastic grinding tools in resinoid bond.

Fine grinding, removal and pre-polishing of silicon carbide in resinoid bond.

- Can be easily adapted to contours

- Generation of the widest range of surface structures (matting, polishing)

Elastic metal decorating tools

Elastic grinding wheels for the removal of metallised ceramic components

Elastic grinding tools in resinoid bond.

- Flexible

- Long lifetime

- Self-adhesive foil possible

| Downloads |

|---|

| Image flyer PDF 817 kb |

Grinding tools for the machining of hip and knee joints

Ceramic bonded diamond grinding tools

Machining of ceramic insert cups in wet grinding (oil).

- Ceramic abrasive layer with low metal support

- Maximum surface quality

| Downloads |

|---|

| Image flyer PDF 3.62 mb |

Grinding tools for the machining of hip joints

Resin and ceramic bonded grinding tools for the machining of steel hip joints.

Machining of steel hip joints in wet grinding using honing sleeves.

- Suitable for various steel alloys.

- Long lifetime

| Downloads |

|---|

| Image flyer PDF 3.62 mb |

Grinding tools in BY systems for the machining of hypodermic needles

Silicon carbide grinding tools in self-sharpening resinoid bond systems.

Resin-bonded grinding tools for the pointing of hypodermic needles.

- Burr-free finish

- Long lifetime

- Best surface finishes

| Downloads |

|---|

| Image flyer PDF 3.62 mb |

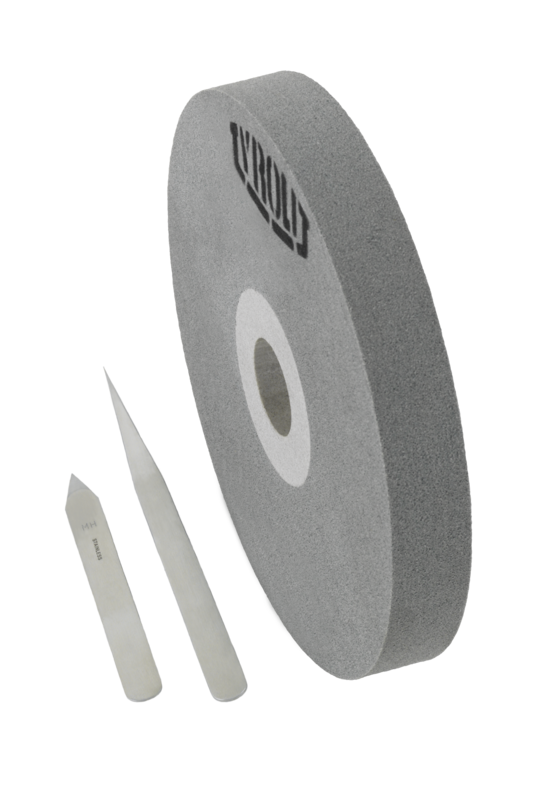

STARTEC XP-F

Grinding wheels for poloshing shank tools

The STARTEC XP-F product line from TYROLIT provides innovative polishing wheels for the cost-efficient polishing of the functional surfaces of shank tools. These tools feature a new resinoid bond with a high wear resistance combined with tailored micro-diamonds. These new specifications can also be produced in customer-specific shapes and dimensions. They guarantee the best surface finish while at the same time delivering maximum precision for the polished tools. Show more Show less

- Best surface finish

- Low wheel wear

- Highest precision

| Downloads |

|---|

| Product flyer PDF 154 kb |

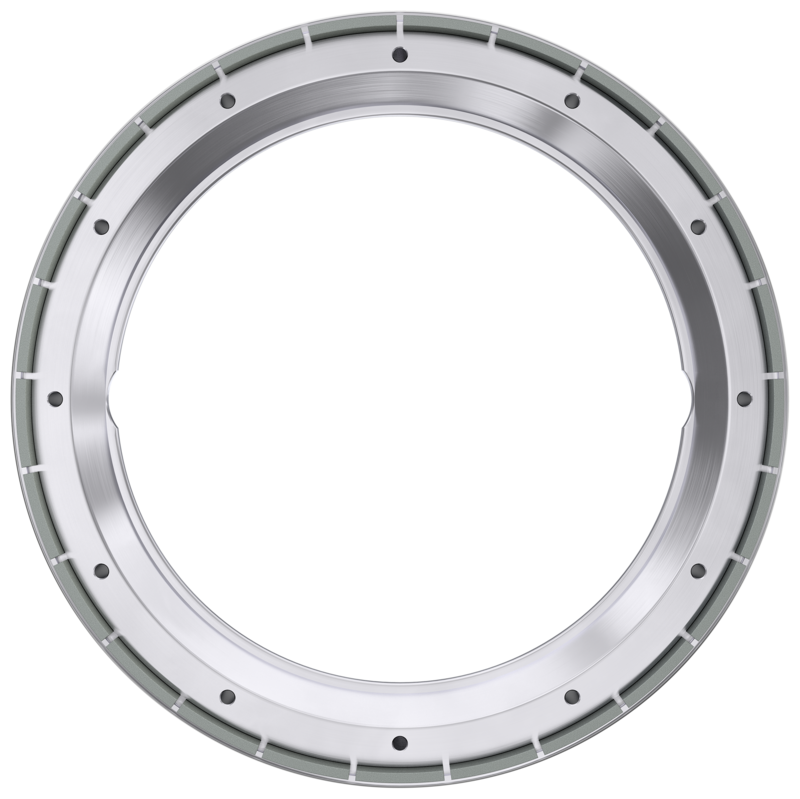

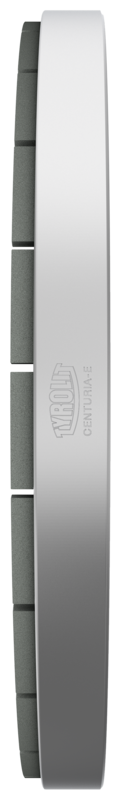

CENTURIA - E

Backgrinding Wheels for the Semiconductor Industry

The product assortment for backgrinding of wafers allows to reach highest quality surfaces with a significant improved Die Strength Ratio. The composition of optimized diamond quality, special bond system and an unique core design produced with an innovative production technology at Asahi, guarantees lowest grinding forces during the grinding process. In combination with specific process adjustments an outstanding economic efficiency can be reached. Show more Show less

- Improved Die Strength Ratio

- Shorter Grinding times

- Stock range

| Downloads |

|---|

| Product flyer PDF 169 kb |