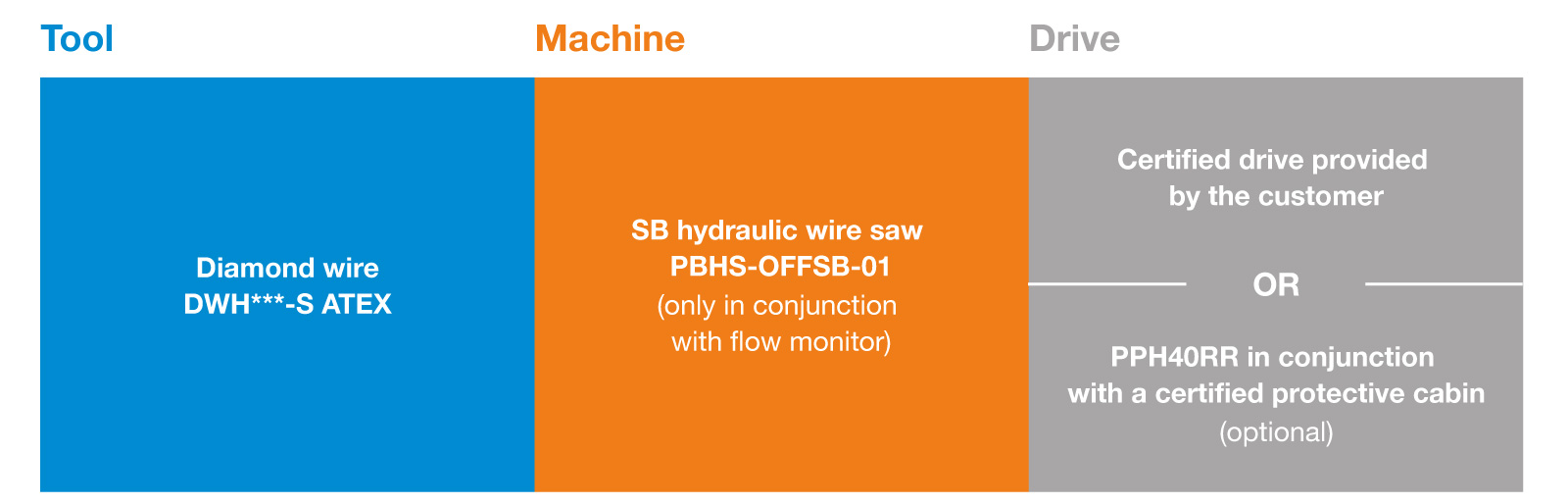

Whether for the controlled decommissioning of offshore installations or nuclear power stations, the expansion and reconstruction of tunnels or for smaller specialist construction projects – TYROLIT is your reliable partner in special construction solutions.

In addition to a wide range of standard products, as well as customisable products, the TYROLIT Project Services Team supports its customers with:

- Feasibility studies

- Planning concepts

- Principle sketches

- Customised products for machines & tools

- Project management

- Training courses