MIRA DDG

Diamond dressing gears for dressing honing rings

TYROLIT's MIRA DDG has made the company into a market and technology leader in the field of diamond dressing gear production. Honing rings are trued and sharpened during the dressing process. Thanks to their high level of reproducibility and cutting ability, MIRA DDG dressing gears guarantee optimum dressing results, the best possible gearing and surface quality as well as long tool lifetime.

- Cutting ability

- Accuracy

- Replating option

- Gear cutting expertise

- System solution

| Downloads |

|---|

| Product flyer PDF 223 kb |

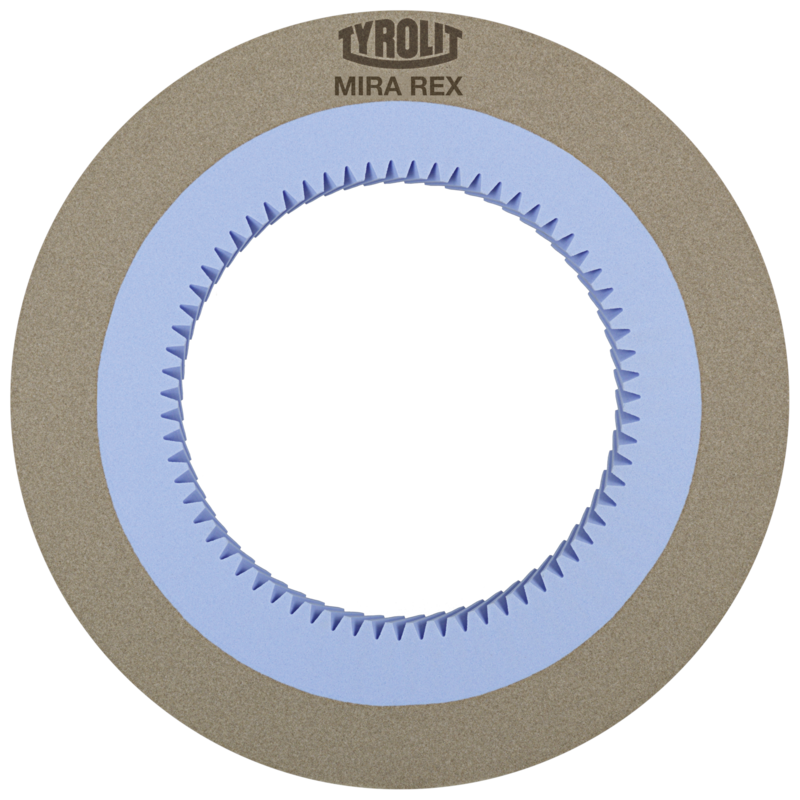

MIRA REX

Ceramic honing rings for tooth flank honing

Over 25 years of experience in gear honing make TYROLIT the market and technology leader in its field. Now, more than ever, the MIRA REX product line has made it possible to provide the optimum technical solution for high-efficiency honing. The continuous further development of specifications regarding hardness and cutting ability guarantees maximum honing performance and long dressing cycles.

- Maximum performance

- Short initial dressing times

- Extremely rapid availability

- System solution

| Downloads |

|---|

| Product flyer PDF 186 kb |

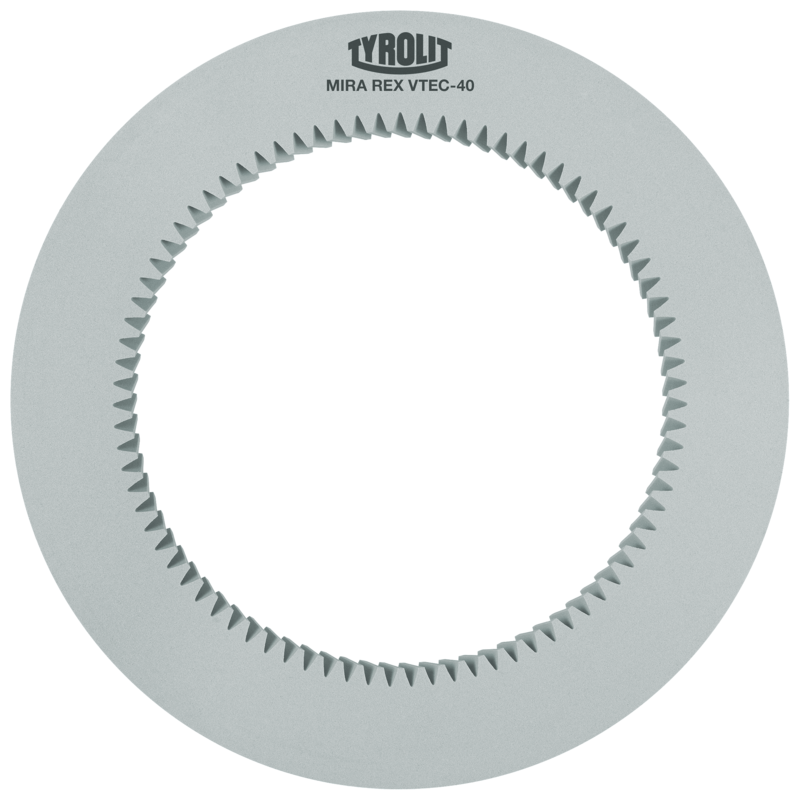

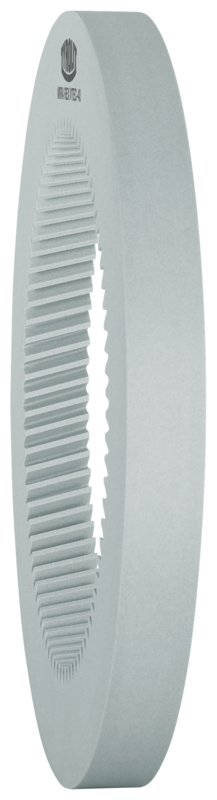

MIRA REX VTEC

Vitrified bonded honing wheels for tooth flank honing for the VSD dressing system

Over 25 years of experience in gear honing make TYROLIT the market and technology leader in this field. With the addition of the MIRA REX VTEC to the product range, we have succeeded in developing technically optimised and adapted honing rings for use with the VSD dressing system. The MIRA REX VTEC honing wheels are available in three different specifications: MIRA REX VTEC-20 standard quality MIRA REX VTEC-30 premium quality MIRA REX VTEC-40 high premium quality Show more Show less

- Reduced wear

- Best economic efficiency

- Worldwide service

- Rapid availability

| Downloads |

|---|

| Product flyer PDF 193 kb |

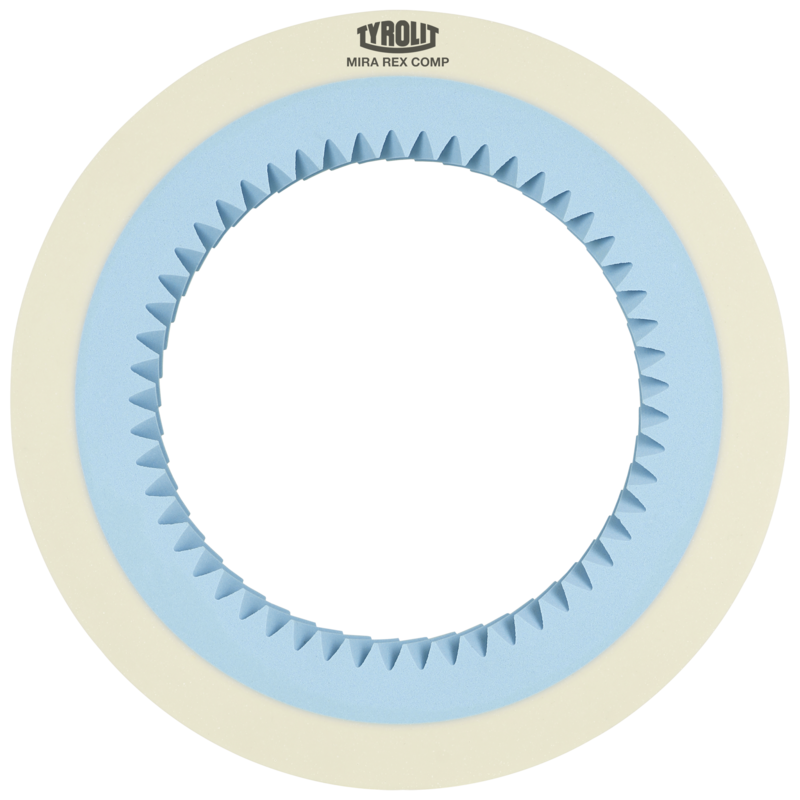

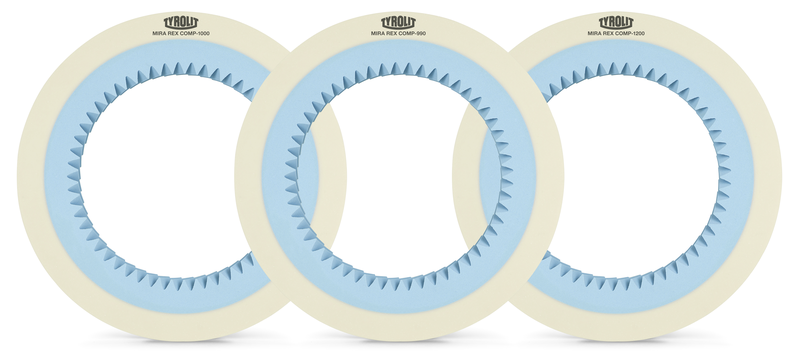

MIRA REX COMP

Vitrified bonded honing wheels for tooth flank honing in composite design

Over 25 years of experience in gear honing make TYROLIT the market and technology leader in this field. With the new 2-zone composite design MIRA REX COMP range, we have succeeded in developing technically optimised and adapted honing wheels for power honing. . The abrasive inner ring is produced using vitrified bonding. The outer ring is made of an PU bonding without abrasive grains. A patent application was filed for this innovative honing wheel design. Show more Show less

- Protection of the tool holder

- Low weight

- Rapid availability

- Best surface results

- Vibration-damping properties

| Downloads |

|---|

| Product flyer PDF 212 kb |