STRATO ULTRA

Vitrified bonded grinding wheels for surface and creep feed grinding.

Tyrolit is the market and technology leader in the field of high-porosity grinding wheels for creep feed grinding. With the STRATO product line, TYROLIT is setting new standards of quality and performance. It has now launched STRATO-ULTRA, representing the next generation of surface and creep feed grinding tools. Particularly in the turbine industry, STRATO ULTRA can be used instead of grinding tools with expensive sintered aluminium oxides without sacrificing performance. Sintered aluminium oxide reacts very aggressively to the dressing tool and consequently generates increased diamond wear. TYROLIT offers its customers profiled grinding tools. Depending on the profile depth, simple edge profiles and customised pre-profiling can significantly reduce set-up times (pre-profiling times) and associated dressing tool wear. Show more Show less

- Reduced grinding times

- Significantly better profile retention

- Cool polished section

- Increased wheel life

- Approved for up to 63 m/s

| Downloads |

|---|

| Product flyer PDF 113 kb |

STRATO ALPHA

Vitrified bonded high performance grinding tools for surface and creep feed grinding

Tyrolit's STRATO ALPHA sets a further milestone in the economical production of turbine blades. Thanks to the new ALPHA technology, these vitrified bonded high-performance grinding wheels provide an exceptionally long lifetime, high profile retention and a particularly cool grinding performance. Show more Show less

- Increased lifetime

- Environmentally friendly

- Cool grinding:

- Reduced grinding time

| Downloads |

|---|

| Product flyer PDF 189 kb |

VIPER ULTRA

Vitrified bonded grinding wheels for surface and creep feed grinding.

With VIPER ULTRA, TYROLIT is setting a new benchmark in the field of creep feed grinding. The improved bonding of the grain and precisely controlled wetting enable the patented VIPER ULTRA bond system to coat the surface of the grain and so greatly improve grain bonding.

- Reduced grinding times

- Significantly better profile retention

- Cool polished section

- Increased wheel life

| Downloads |

|---|

| Product flyer PDF 217 kb |

VIPER ALPHA

Ceramic bonded high performance grinding tools for the patented Viper grinding process

With the VIPER ALPHA, TYROLIT is setting a further milestone in the economical production of turbine blades. Thanks to the new ALPHA technology, these vitrified bonded high-performance grinding wheels convince with exceptional lifetime, high profile retention and cool grinding. Show more Show less

- Increased lifetime

- Environmentally-friendly

- Cool grinding

- High profile retention

| Downloads |

|---|

| Product flyer PDF 209 kb |

Grinding tools for the machining of industrial knives

Grinding tools in ceramic and resinoid bond.

Pre and finish grinding (polishing) mostly with resinoid bonds in wet grinding.

- High stock removal rate in the shortest time

- Good surface finishes

| Downloads |

|---|

| Image flyer PDF 2.46 mb |

STRATO SA

Galvanic bonded grinding tools for creep feed and surface grinding

With the STRATO SA product line, TYROLIT is offering grinding tools with electroplated superabrasives that are predominantly used in the turbine industry. These grinding tools guarantee high profile accuracy and the best process stability during the creep feed process. In applications such as the machining of radial grooves, this produces extremely precise grinding results at low unit costs. Show more Show less

- Maximum profile accuracy

- Replating-compatible

- Maximum lifetimes

| Downloads |

|---|

| Product flyer PDF 132 kb |

STRATO SA

Electroplated CBN tools forcreep feed and surface grinding

With the STRATO SA product line, TYROLIT offers, for the first time, tools with superabrasives, which enable optimum process stability in the creep feed grinding process with their uniform profile dimensions. Their high profile retention ensures precise grinding results, particularly in difficult applications.

- Customised production

- Longest tool life

- Replating option

- Maximum profile accuracy

- Constant optimisation

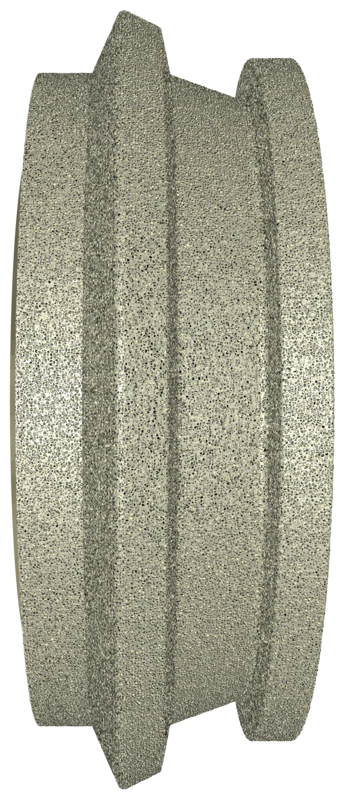

DressTec NGR

Next Generation of Diamond Roller Dressers

TYROLIT have extended the portfolio of diamond roller dressers with an exciting new assortment: DressTec NGR. This new product line enables TYROLIT to offer the fastest delivery time for roller dressers in the market, whilst maintaining the highest precision and quality. This is achieved thanks to the very latest manufacturing technologies, new processing steps and premium measuring equipment at the company’s state-of-the- art plant in Neuenrade, Germany. DressTec NGR combines quality, reproducibility and precision features with the fastest speed to market. This is unique within the industry. Show more Show less

- Fastest speed to market

- Planning security

- Increased flexibility

- Unparalleled investment

| Downloads |

|---|

| Product flyer PDF 242 kb |