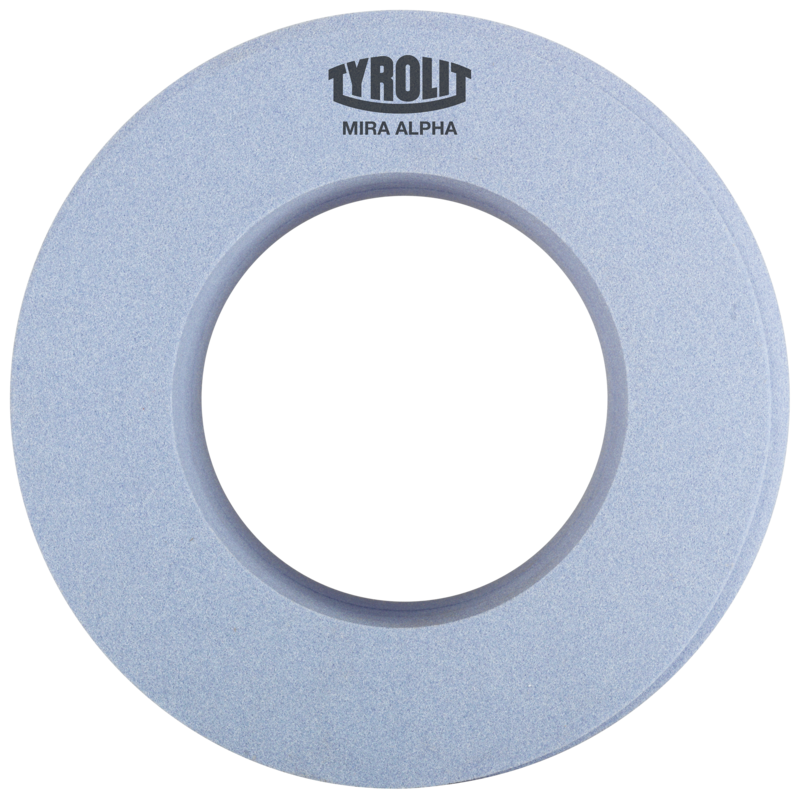

MIRA ALPHA

Vitrified bonded worm grinding wheels for continuous generating grinding of gears

The product line MIRA ALPHA has been specially developed for continuous generating grinding of gears. It is a product update to the product line MIRA ICE. With the new ALPHA technology from TYROLIT previously unattained results in terms of economy and cool grinding can be achieved. Show more Show less

- Best cost efficiency

- Cool grinding

- Highest process reliability

- Improved surface qualities

| Downloads |

|---|

| Product flyer PDF 227 kb |

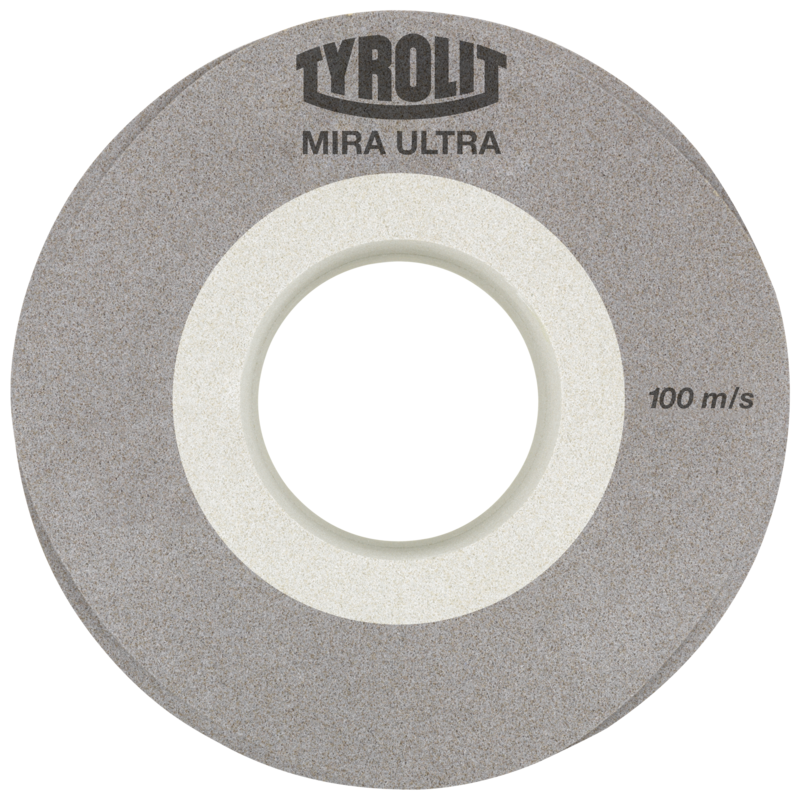

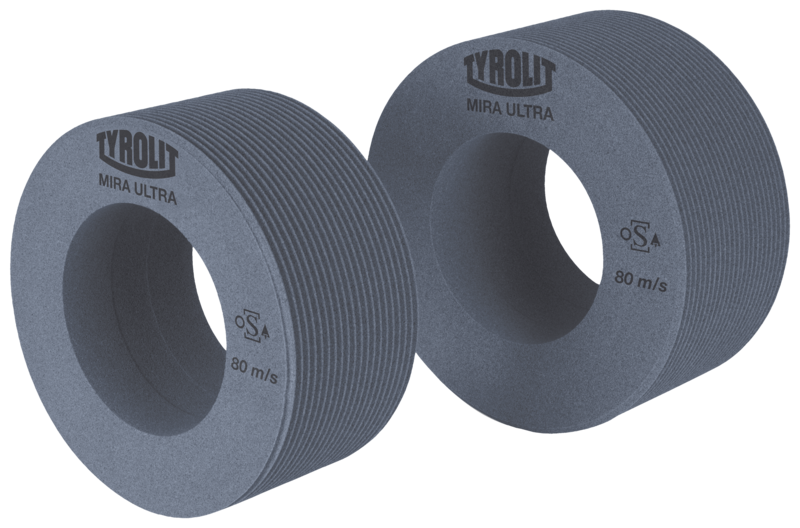

MIRA ULTRA

Vitrified bonded worm grinding wheels for continuous generating grinding of gears

TYROLIT has developed the MIRA Ultra product line specifically for the continuous generating grinding of gears. All specifications are produced without the addition of sintered aluminium oxide and combine outstanding performance data with optimum economic efficiency. The innovative grinding wheel structure was specially designed for operating speeds of up to 100 m/s and allows reliable operation on modern high-speed machines.

- Higher operating speed

- Maximum process stability

- Extremely rapid availability

- The best economic efficiency

- Cool polished section

| Downloads |

|---|

| Product flyer PDF 248 kb |

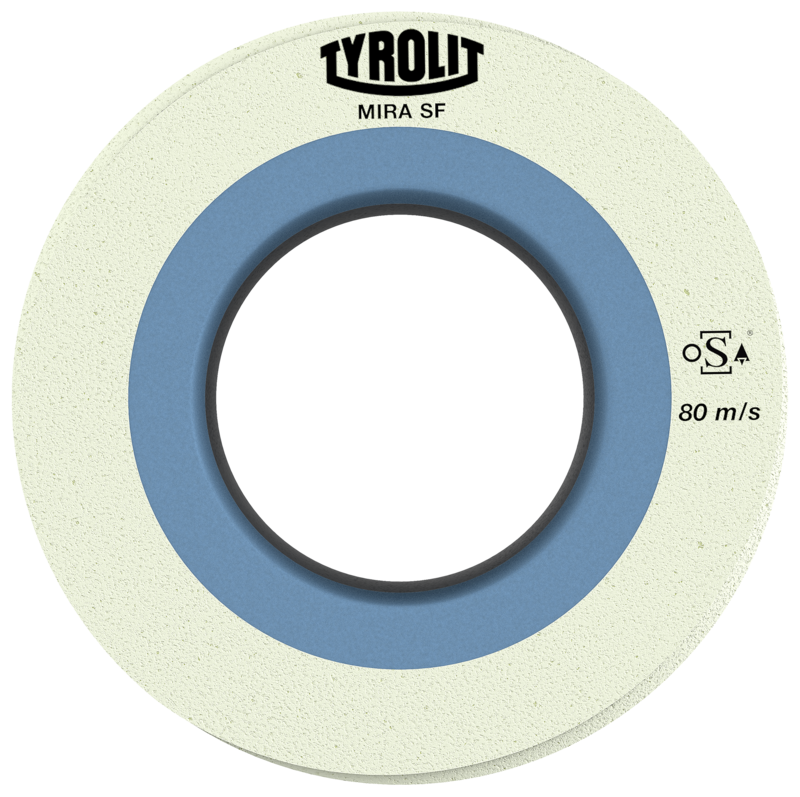

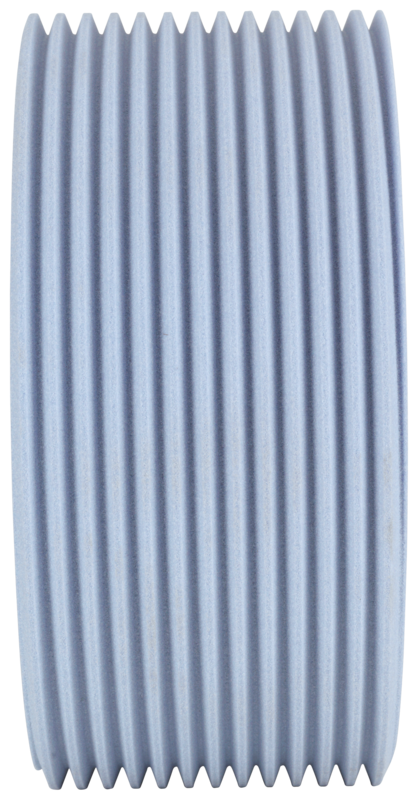

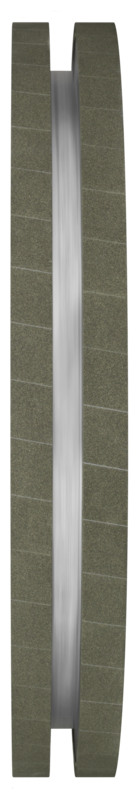

MIRA SF

2-zone gear grinding wheels for continuous generating grinding and superfinishing of gears

The MIRA SF product line has been specifically developed for superfinishing (SF) gears during continuous generating grinding. The worm grinding wheel is designed as a 2-zone tool with a vitrified bonded zone and a resin bonded zone. The vitrified zone is used for pre-grinding and finish grinding, while the resin zone is used for superfinishing. This innovative tool design meets the high surface requirements of the automotive and transmission industries for polished surfaces on tooth flanks. Show more Show less

- Superfinishing of gear profiles

- 2-zone worm grinding wheel

- Vs 80 m/s

- Wide variety of specifications

| Downloads |

|---|

| Product flyer PDF 913 kb |

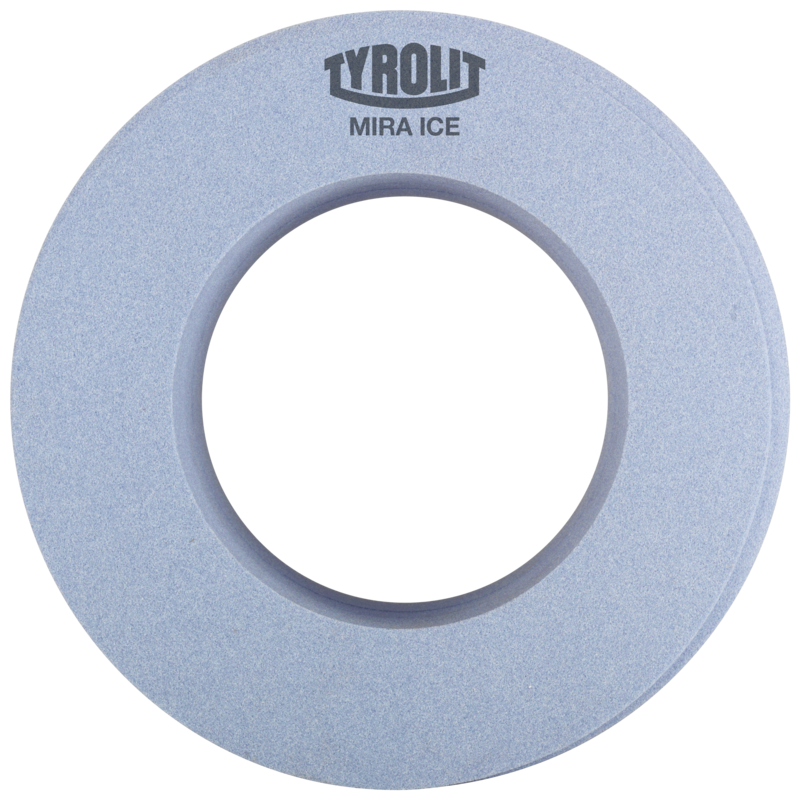

MIRA ICE

Vitrified bonded worm grinding wheels for continuous genrating grinding of gears

The MIRA ICE product line has been specially developed for the continuous generating grinding of gears. A new kind of development approach enables unprecedented results to be achieved in terms of economic efficiency and cool grinding.

- Shorter grinding times

- Longer tool life

- Highest process stability

- High-precision pre-profiling

MIRA DDS

Diamond-dressing tools for dressing of gear grinding wheels for continous generating gear grinding

More than 25 years of experience in hard fine finishing of gears make TYROLIT the market and technology leader in this field. TYROLIT extends the MIRA product assortment for hard fine finishing of gears with the MIRA DDS dressing tools, for dressing in continous generating gear grinding. MIRA DDS dressing tools guarantee best gear qualities and a reproducible work result. Show more Show less

- Quality

- System solution

- Range

- Engineering

- Wear protection

| Downloads |

|---|

| Product flyer PDF 264 kb |

MIRA DDG

Diamond dressing gears for dressing honing rings

TYROLIT's MIRA DDG has made the company into a market and technology leader in the field of diamond dressing gear production. Honing rings are trued and sharpened during the dressing process. Thanks to their high level of reproducibility and cutting ability, MIRA DDG dressing gears guarantee optimum dressing results, the best possible gearing and surface quality as well as long tool lifetime.

- Cutting ability

- Accuracy

- Replating option

- Gear cutting expertise

- System solution

| Downloads |

|---|

| Product flyer PDF 223 kb |

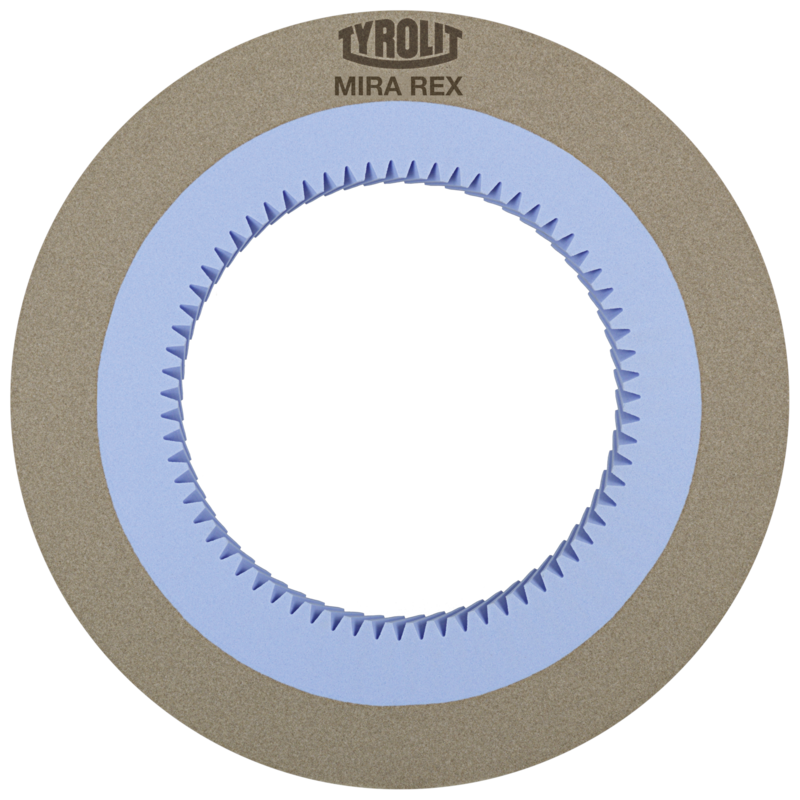

MIRA REX

Ceramic honing rings for tooth flank honing

Over 25 years of experience in gear honing make TYROLIT the market and technology leader in its field. Now, more than ever, the MIRA REX product line has made it possible to provide the optimum technical solution for high-efficiency honing. The continuous further development of specifications regarding hardness and cutting ability guarantees maximum honing performance and long dressing cycles.

- Maximum performance

- Short initial dressing times

- Extremely rapid availability

- System solution

| Downloads |

|---|

| Product flyer PDF 186 kb |

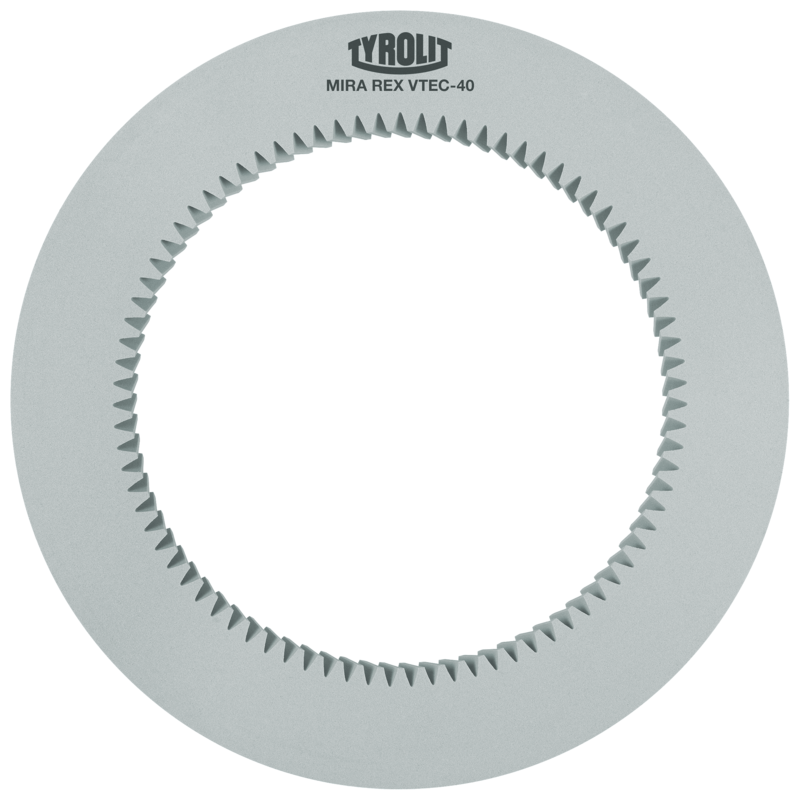

MIRA REX VTEC

Vitrified bonded honing wheels for tooth flank honing for the VSD dressing system

Over 25 years of experience in gear honing make TYROLIT the market and technology leader in this field. With the addition of the MIRA REX VTEC to the product range, we have succeeded in developing technically optimised and adapted honing rings for use with the VSD dressing system. The MIRA REX VTEC honing wheels are available in three different specifications: MIRA REX VTEC-20 standard quality MIRA REX VTEC-30 premium quality MIRA REX VTEC-40 high premium quality Show more Show less

- Reduced wear

- Best economic efficiency

- Worldwide service

- Rapid availability

| Downloads |

|---|

| Product flyer PDF 193 kb |

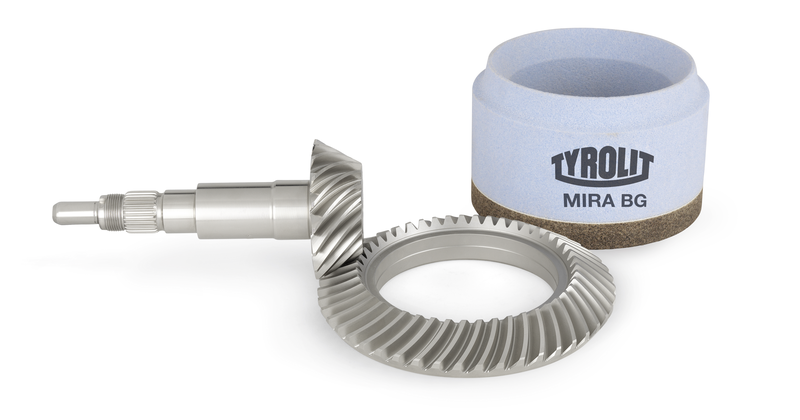

MIRA BG

Cup wheels for grinding bevel gears

With the MIRA BG product line, TYROLIT offers an optimum solution for grinding bevel gears. More stringent quality requirements make hard finishing by grinding increasingly necessary.

- High productivity

- Low heat build up

- Maximum profile retention

- Available with or without mounting plate

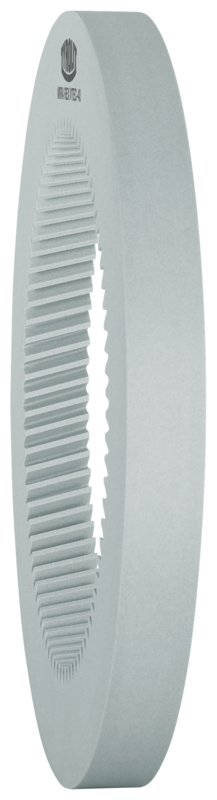

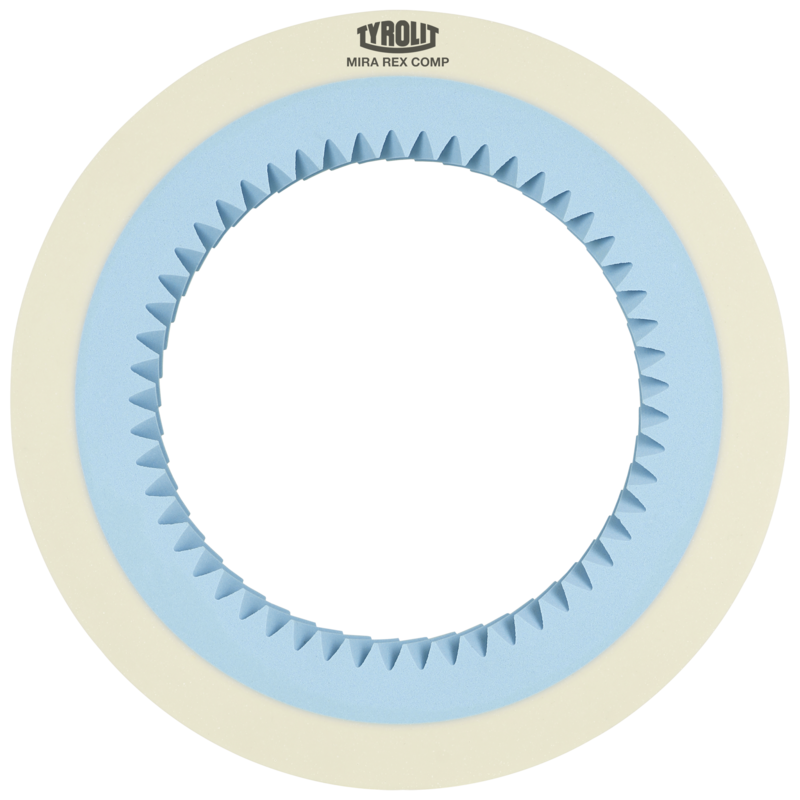

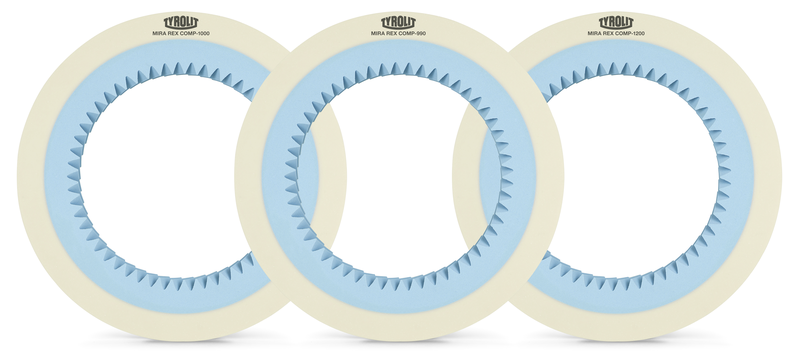

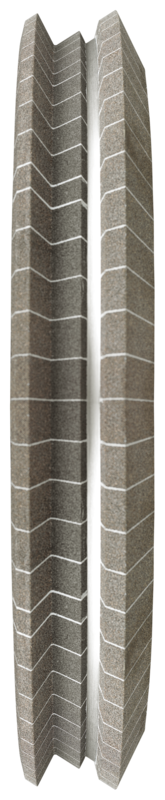

MIRA REX COMP

Vitrified bonded honing wheels for tooth flank honing in composite design

Over 25 years of experience in gear honing make TYROLIT the market and technology leader in this field. With the new 2-zone composite design MIRA REX COMP range, we have succeeded in developing technically optimised and adapted honing wheels for power honing. . The abrasive inner ring is produced using vitrified bonding. The outer ring is made of an PU bonding without abrasive grains. A patent application was filed for this innovative honing wheel design. Show more Show less

- Protection of the tool holder

- Low weight

- Rapid availability

- Best surface results

- Vibration-damping properties

| Downloads |

|---|

| Product flyer PDF 212 kb |

GENIS 2

VITRIFIED-BONDED CBN GRINDING TOOLS FOR EXTERNAL CYLINDRICAL GRINDING

With the GENIS 2 product line, TYROLIT defines a new performance level and a wider range of applications for external cylindrical grinding with vitrified-bonded CBN tools. GENIS 2 is characterised by a high-strength bond with excellent moistening properties, which securely binds the CBN grain. Low bond volumes enable very porous, cool-grinding and extremely easy-cutting specifications with a long lifetime. Show more Show less

- Optimum grain utilisation

- High economic efficiency

- High running precision

- Wide range of applications

| Downloads |

|---|

| Product flyer PDF 150 kb |

GENIS

External cylindrical grinding with vitrified bonded CBN high-performance grinding tools

Following intensive research, TYROLIT has succeeded in developing GENIS - a bond system that ensures optimum wetting and coating of the CBN grain, even with extremely low bond content. By selecting the composition of the bond, at the right firing conditions crystallisation is controlled in a targeted manner. This enables the production of porous textures with high mechanical strength, which feature maximum resistance to the effect of cooling lubricants. The cool grinding specifications of our GENIS highest performance tools enable you to purposely reduce grinding forces and so make the most efficient use of the CBN grain. In all applications, practical experience shows that reduced grinding forces enable minimal wear and maximum profile retention. Show more Show less

- High adhesion strength of the CBN and optimum resistance to cooling lubricants

- New high-performance CBN grain qualities

- Optimised chipping space (porosity) and cool grinding

- Reduced grinding forces

- Neutral zone

| Downloads |

|---|

| Product flyer PDF 1.90 mb |

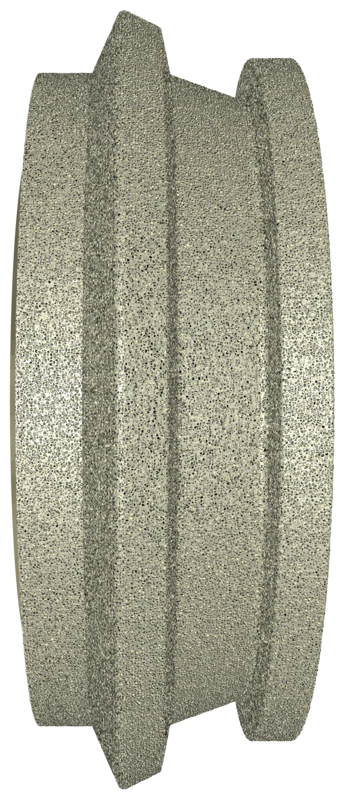

GENIS CF

Vitrified bonded CBN grinding tools with composite cores for external cylindrical grinding

With GENIS CF, TYROLIT is extending the performance spectrum of the GENIS product line with an innovative, fibre-reinforced composite core for numerous external cylindrical grinding applications. In addition to a weight reduction of up to 80%, this tool design features special damping characteristics, which result in improved grinding results and a longer lifetime.

- Lower weight

- Best damping

- High economic efficiency

- Replating option

- Simultaneous machining

| Downloads |

|---|

| Product flyer PDF 213 kb |

CSS ULTRA

High performance grinding tools for external cylindrical grinding and thread grinding

With CSS ULTRA, TYROLIT has managed to restructure the micro-architecture of the grinding wheel with lasting effect by using high quality components and innovative sintering technology. This enables the abrasive grain to withstand much greater loads during use without breaking away prematurely. These improvements result in maximum profile retention combined with minimal wear.

- Optimum profile retention

- Cool grinding (no burning)

| Downloads |

|---|

| Product flyer PDF 144 kb |

POLARIS BASIC / POLARIS PLUS

Electroplated CBN grinding tools for external plunge cut grinding

With its POLARIS product line, TYROLIT is the market and technology leader in the production of galvanic bonded grinding tools. Cutting-edge production equipment, manufacturing know-how and application expertise are essential for maximum tool lives. Even the smallest amount of axial and radial run out or the slightest imbalance can reduce the service life of the tool. Additionally with the POLARIS PLUS variant, the zones with the highest levels of tool wear can be specifically reinforced, extending the life of the grinding wheel even further. Show more Show less

- Individual production

- Maximum lifetimes

- Replating-compatible

- Maximum profile accuracy

- Constant optimisation

| Downloads |

|---|

| Product flyer PDF 167 kb |

COLUMBIA SA

Vitrified bonded CBN grinding tools for internal cylindrical and profile grinding.

With COLUMBIA SA, TYROLIT has created an innovativeproduct line for internal cylindrical and profile grinding withCBN. The VCSA bond, which was specially developedfor this purpose, further enhances the unique propertiesof CBN. The smaller wheel dimensions utilised withininternal cylindrical grinding are particularly suitable for theeconomical use of CBN grinding wheels.

- Improved cool grindingbehaviour

- Improved economic efficiency

- Highest process stability

- Additionally even using emulsionbased coolants

| Downloads |

|---|

| Product flyer PDF 198 kb |

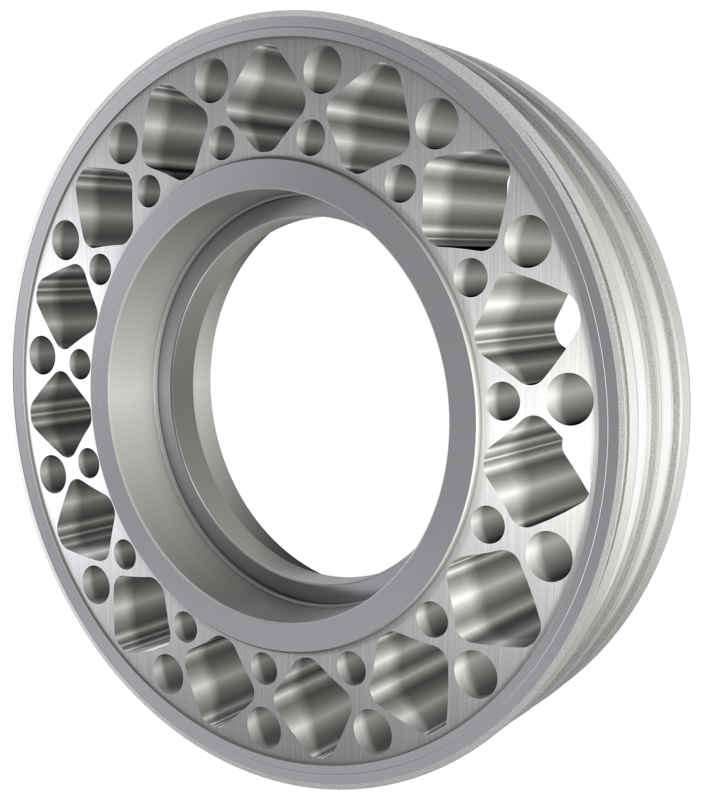

POLARIS BASIC LW / POLARIS PLUS LW

Electroplated CBN grinding wheel with lightweight core for external cylindrical grinding

With the POLARIS LW product line, TYROLIT is a pioneer and technology leader in the area of lightweight electroplated grinding tools. Through targeted material reduction, the wheel weight has been significantly reduced. stock removal rate at the core is not random, but is calculated using a computational FEM analysis (Finite Element Method). This means that deformations and potential performance losses can be excluded. Through use of the lightweight POLARIS LW version, the maintenance intervals at the grinding machines can be reduced and handling significantly simplified for personnel in production. Show more Show less

- Weight optimisation

- Maximum tool life

- Replating-compatible

- Computational FEM simulation

DressTec NGR

Next Generation of Diamond Roller Dressers

TYROLIT have extended the portfolio of diamond roller dressers with an exciting new assortment: DressTec NGR. This new product line enables TYROLIT to offer the fastest delivery time for roller dressers in the market, whilst maintaining the highest precision and quality. This is achieved thanks to the very latest manufacturing technologies, new processing steps and premium measuring equipment at the company’s state-of-the- art plant in Neuenrade, Germany. DressTec NGR combines quality, reproducibility and precision features with the fastest speed to market. This is unique within the industry. Show more Show less

- Fastest speed to market

- Planning security

- Increased flexibility

- Unparalleled investment

| Downloads |

|---|

| Product flyer PDF 242 kb |

GENIS 2 LW

Vitrified-Bonded CBN grinding wheel with lightweight core for external cylindrical grinding

With the GENIS 2 LW product line, TYROLIT is a pioneer and technology leader in the area of lightweight vitrified-bonded grinding tools. Through targeted material reduction, the wheel weight has been significantly reduced. The stock removal rate at the core is not random, but is calculated using a computational FEM analysis (Finite Element Method). This means that deformations and potential performance losses can be excluded. Through use of the lightweight GENIS 2 LW version, the maintenance intervals at the grinding machines can be reduced and handling significantly simplified for personnel in production. Show more Show less

- Weight optimisation

- Replating-compatible

- Maximum tool life

- Computational FEM simulation

| Downloads |

|---|

| Product flyer PDF 169 kb |

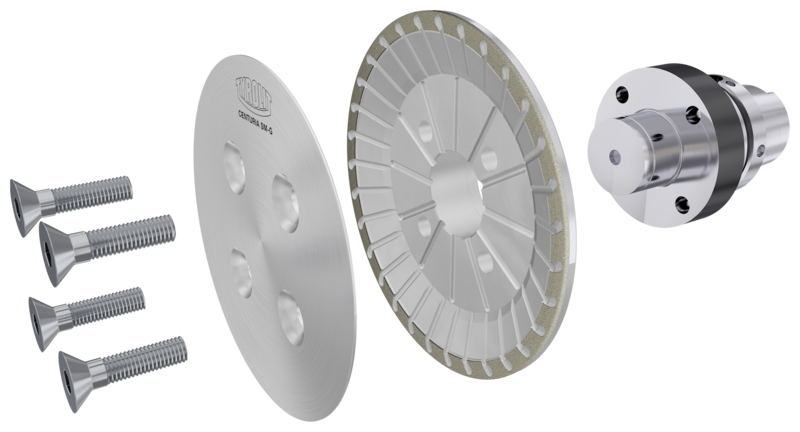

CENTURIA SM-G

Diamond grinding tools for surface grinding of aluminium and bimetallic engine blocks and cylinder heads

With the CENTURIA SM-G product line, TYROLIT offers an economical grinding solution for end-face machining of engine blocks and cylinder heads. The big challenge is achieving a stable surface quality over the entire lifetime of the tool, thereby minimising the scrap rate. Conventional milling tools can cause problems with chip transport as well as surface flaws in the soft aluminium base alloy. With bimetallic blocks, the problem is further exacerbated by the much harder alloy of the cylinder liner. CENTURIA SM-G tools significantly reduce set-up costs due to the elimination of time-consuming assembly work on the milling tool (cutting inserts). They can also be replated multiple times, making them an economical alternative to conventional milling tools. Show more Show less

- Stable process

- Flexibility

- Increased quality

- Wide range of specifications

| Downloads |

|---|

| Product flyer PDF 198 kb |

GENIS 2 N-LW

Vitrified-bonded CBN grinding tools with natural fibre-reinforced core for external cylindrical grinding

TYROLIT is setting new standards for external cylindrical grinding using ceramic CBN with the GENIS 2 N-LW product line. The extremely low density of the patented core material N-LW delivers significant weight savings. GENIS 2 N-LW tools are lighter and most of all less expensive than comparable tools with a CFRP core. The products can be approved for wheel peripheral speeds of up to 140 m/s. The material has excellent damping behaviour and is designed with a high-precision steel mounting in the bore area. This means that GENIS 2 N-LW cores can be replaced a number of times and used in production. Show more Show less

- Significant weight reduction

- Damping properties

- Wide range of applications

- Approved for 140 m/s

| Downloads |

|---|

| Product flyer PDF 259 kb |