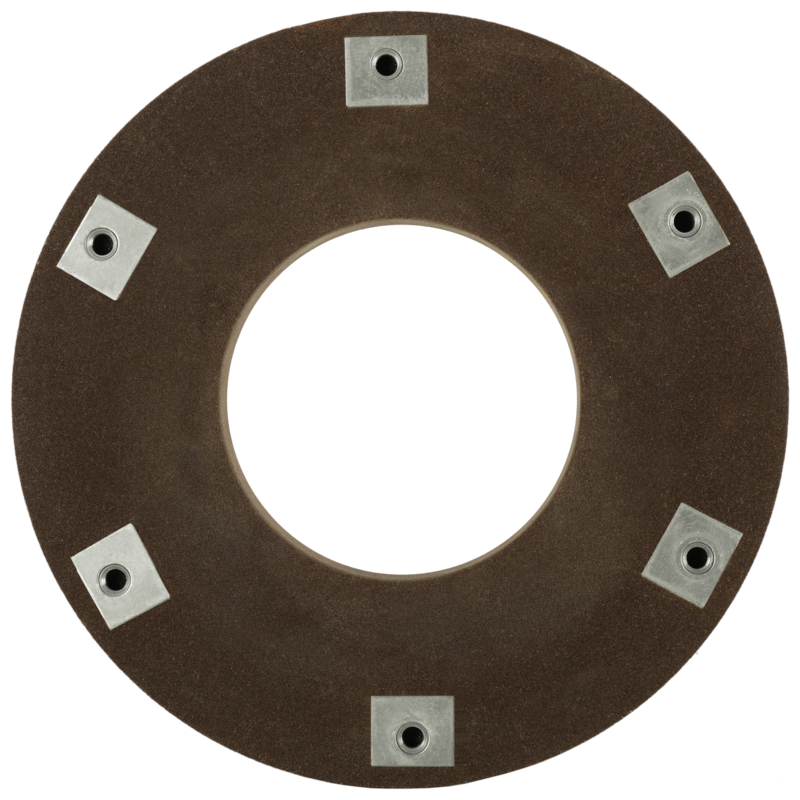

CENTURIA

Resin-bonded grinding tools for side grinding

With its CENTURIA product line, Tyrolit offers a complete range of conventional, resin-bonded tools for surface grinding. Different face grinding methods are used for rational production of functional surfaces with high requirements relating to evenness, plane parallelism and surface finish. Either both faces are machined simultaneously (double side face grinding), or just one face is machined using single wheels, segments, rings or cups. The components are often manufactured in mass production, which means that there are high requirements with respect to process stability. Show more Show less

- Constant grinding properties even over a long period of use

- Cool grinding (no burning)

- Long service life of the grinding tool

COLUMBIA

Vitrified bonded grinding tools for internal cylindrical grinding

COLUMBIA grinding wheels from TYROLIT bridge the technological gap between grinding tools made of fused aluminium oxide and superabrasives. For internal cylindrical grinding applications, in particular, these products of specially bonded sintered aluminium oxide develop their full potential and make possible previously unparalleled levels of performance.

- High quality of groundrings

- The best economic efficiency

- Maximum process stability

| Downloads |

|---|

| Product flyer PDF 216 kb |

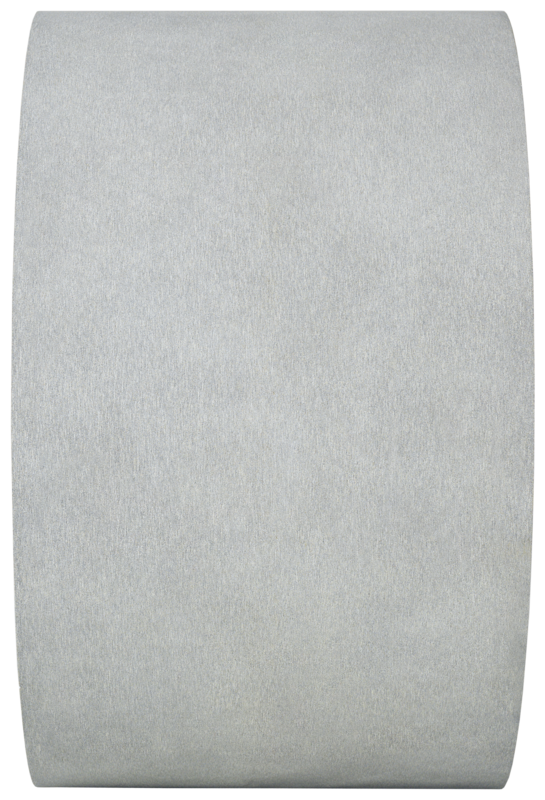

CSS REGULATOR

The regulating wheel for centerless grinding

Through the use of centreless grinding in through-feed and plunge cut grinding, round components can be produced with particular precision and efficiency. Here, the regulating wheel controls the grinding process and therefore has a decisive influence on the quality of the produced components. The CSS REGULATOR from TYROLIT is manufactured as a unitised version. The extremely high compaction ensures uniform quality of the regulating wheel. Show more Show less

- Excellent profile retention

- Good coefficient of friction

- Constant grinding pressure

| Downloads |

|---|

| Product flyer PDF 150 kb |

CSS ULTRA

High performance grinding tools for external cylindrical grinding and thread grinding

With CSS ULTRA, TYROLIT has managed to restructure the micro-architecture of the grinding wheel with lasting effect by using high quality components and innovative sintering technology. This enables the abrasive grain to withstand much greater loads during use without breaking away prematurely. These improvements result in maximum profile retention combined with minimal wear.

- Optimum profile retention

- Cool grinding (no burning)

| Downloads |

|---|

| Product flyer PDF 144 kb |

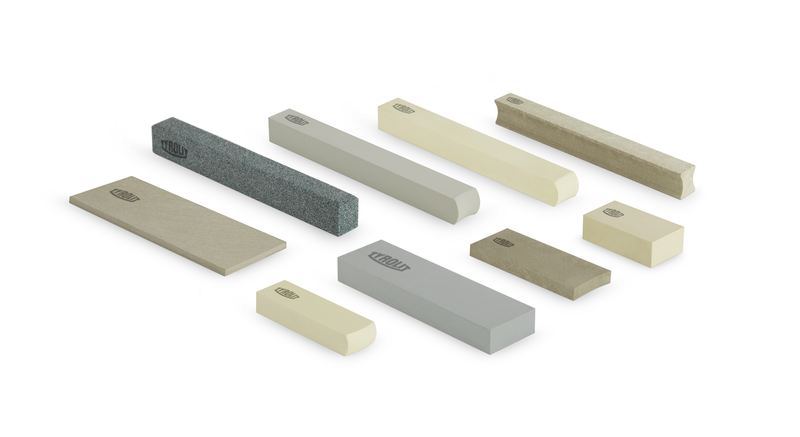

Honing and superfinishing stones

Vitrified and resin-bonded tools for honing and superfinishing

Honing and superfinishing stones are made from conventional abrasives (aluminium oxide and silicon carbide) as standard. However, Tyrolit also produces these tools using superabrasives (diamond and CBN). Honing and superfinishing is used on components with especially high demands concerning the surface finish and geometry. The demands on the honing and superfinishing stones are also correspondingly high. Show more Show less

- Consistent quality

- Good stock removal

- Good surface finish

COLUMBIA SA

Vitrified bonded CBN grinding tools for internal cylindrical and profile grinding.

With COLUMBIA SA, TYROLIT has created an innovativeproduct line for internal cylindrical and profile grinding withCBN. The VCSA bond, which was specially developedfor this purpose, further enhances the unique propertiesof CBN. The smaller wheel dimensions utilised withininternal cylindrical grinding are particularly suitable for theeconomical use of CBN grinding wheels.

- Improved cool grindingbehaviour

- Improved economic efficiency

- Highest process stability

- Additionally even using emulsionbased coolants

| Downloads |

|---|

| Product flyer PDF 198 kb |