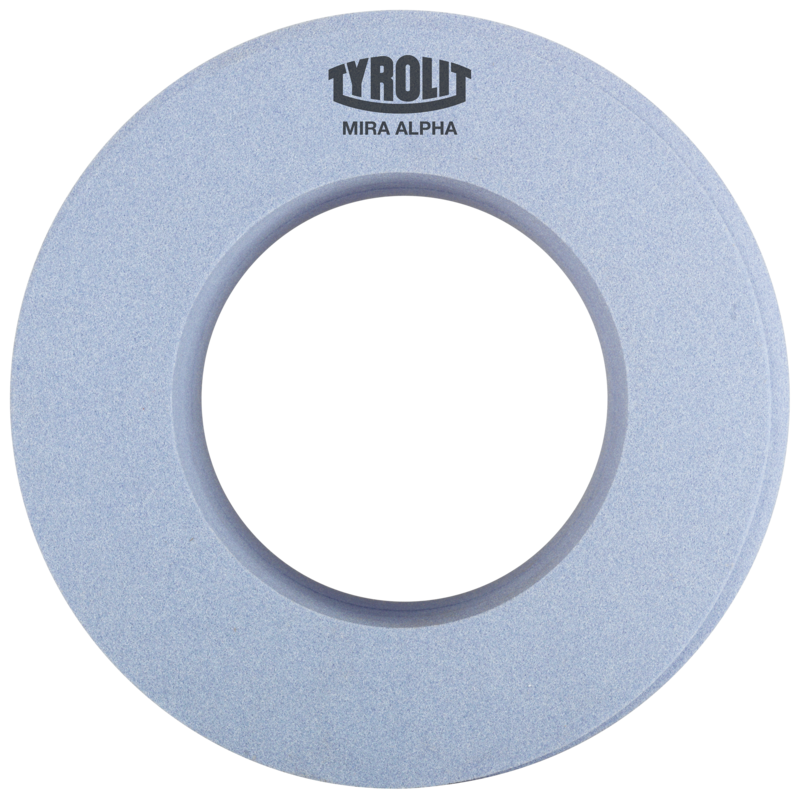

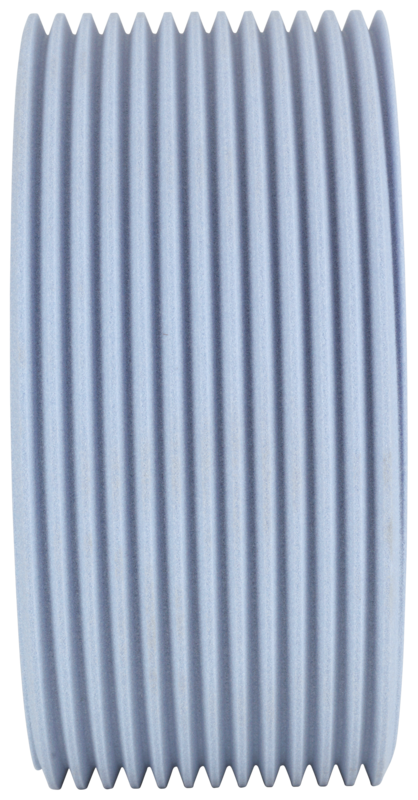

MIRA ALPHA

Vitrified bonded worm grinding wheels for continuous generating grinding of gears

The product line MIRA ALPHA has been specially developed for continuous generating grinding of gears. It is a product update to the product line MIRA ICE. With the new ALPHA technology from TYROLIT previously unattained results in terms of economy and cool grinding can be achieved. Show more Show less

- Best cost efficiency

- Cool grinding

- Highest process reliability

- Improved surface qualities

| Downloads |

|---|

| Product flyer PDF 227 kb |

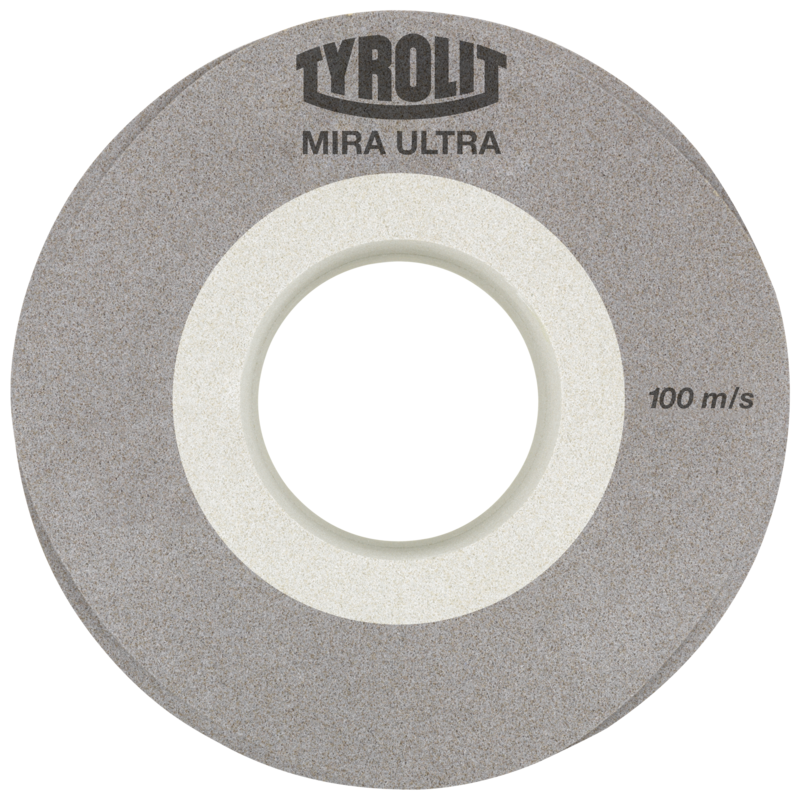

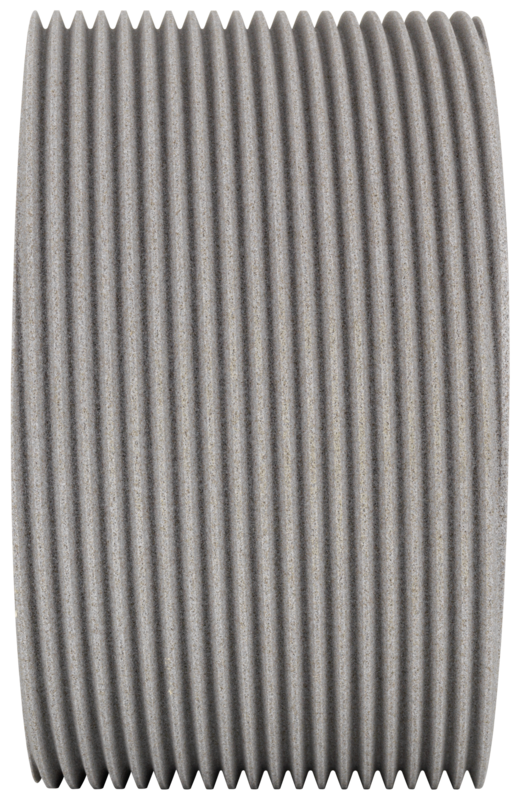

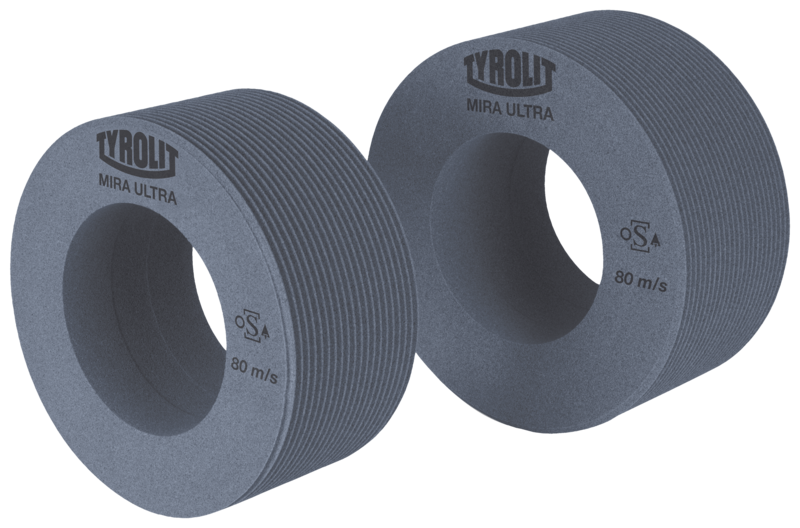

MIRA ULTRA

Vitrified bonded worm grinding wheels for continuous generating grinding of gears

TYROLIT has developed the MIRA Ultra product line specifically for the continuous generating grinding of gears. All specifications are produced without the addition of sintered aluminium oxide and combine outstanding performance data with optimum economic efficiency. The innovative grinding wheel structure was specially designed for operating speeds of up to 100 m/s and allows reliable operation on modern high-speed machines.

- Higher operating speed

- Maximum process stability

- Extremely rapid availability

- The best economic efficiency

- Cool polished section

| Downloads |

|---|

| Product flyer PDF 248 kb |

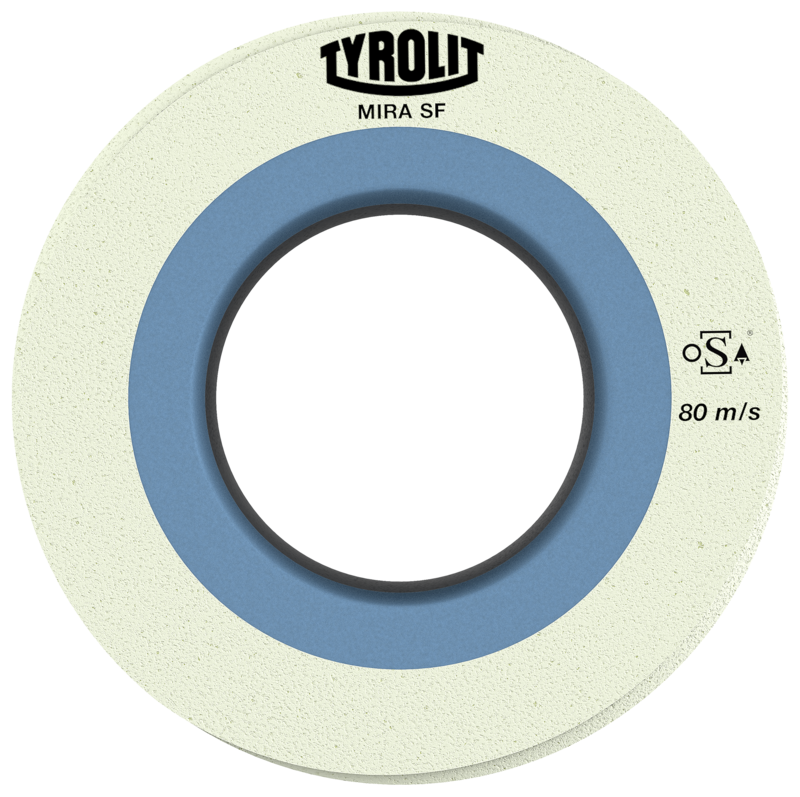

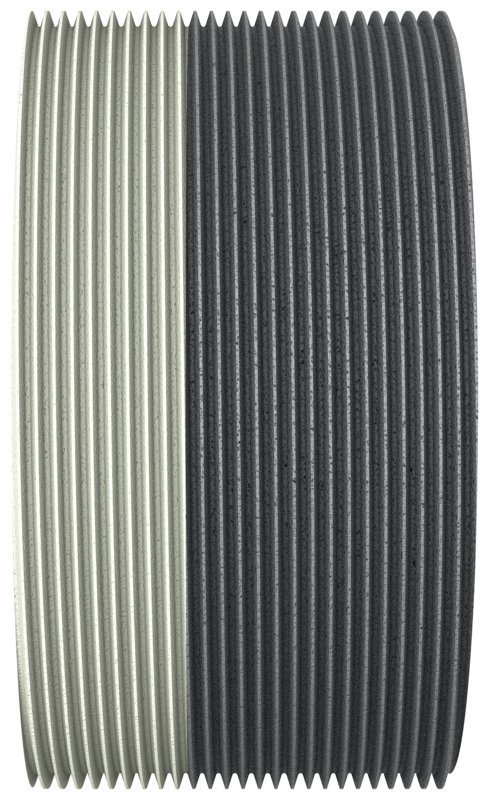

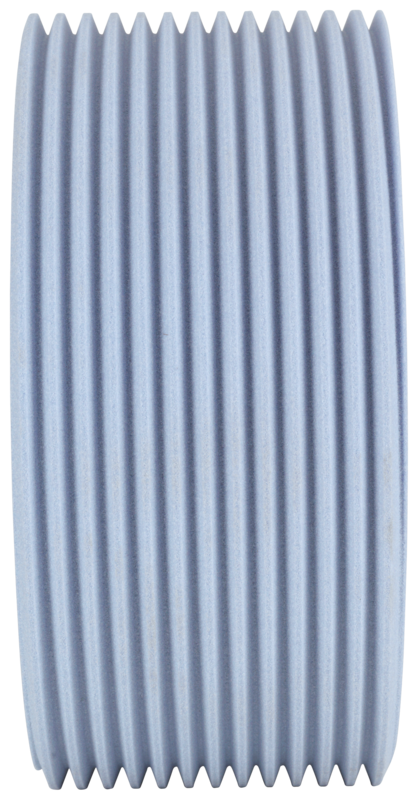

MIRA SF

2-zone gear grinding wheels for continuous generating grinding and superfinishing of gears

The MIRA SF product line has been specifically developed for superfinishing (SF) gears during continuous generating grinding. The worm grinding wheel is designed as a 2-zone tool with a vitrified bonded zone and a resin bonded zone. The vitrified zone is used for pre-grinding and finish grinding, while the resin zone is used for superfinishing. This innovative tool design meets the high surface requirements of the automotive and transmission industries for polished surfaces on tooth flanks. Show more Show less

- Superfinishing of gear profiles

- 2-zone worm grinding wheel

- Vs 80 m/s

- Wide variety of specifications

| Downloads |

|---|

| Product flyer PDF 913 kb |

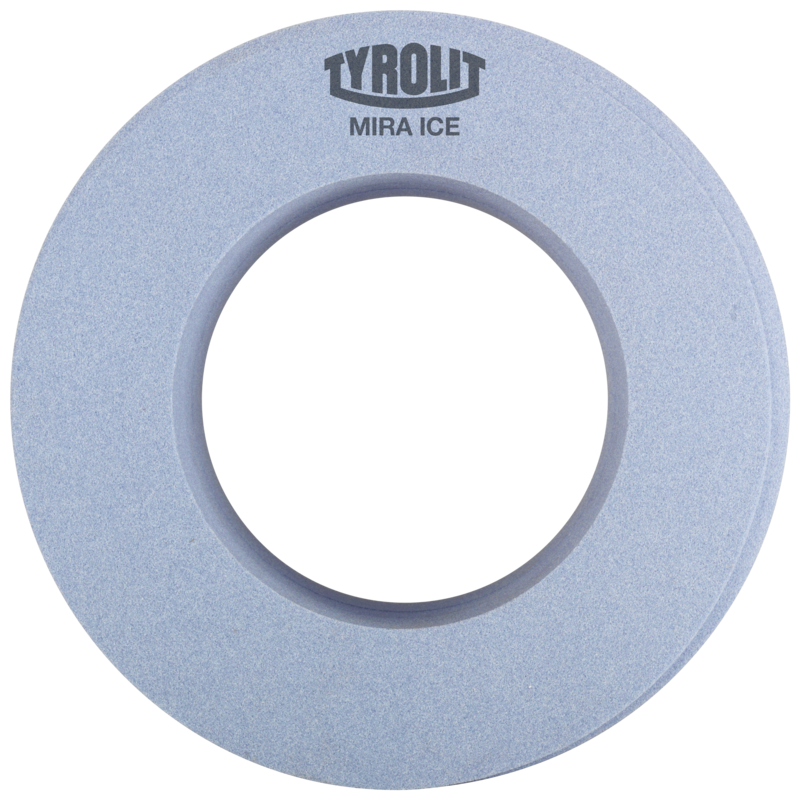

MIRA ICE

Vitrified bonded worm grinding wheels for continuous genrating grinding of gears

The MIRA ICE product line has been specially developed for the continuous generating grinding of gears. A new kind of development approach enables unprecedented results to be achieved in terms of economic efficiency and cool grinding.

- Shorter grinding times

- Longer tool life

- Highest process stability

- High-precision pre-profiling

MIRA DDS

Diamond-dressing tools for dressing of gear grinding wheels for continous generating gear grinding

More than 25 years of experience in hard fine finishing of gears make TYROLIT the market and technology leader in this field. TYROLIT extends the MIRA product assortment for hard fine finishing of gears with the MIRA DDS dressing tools, for dressing in continous generating gear grinding. MIRA DDS dressing tools guarantee best gear qualities and a reproducible work result. Show more Show less

- Quality

- System solution

- Range

- Engineering

- Wear protection

| Downloads |

|---|

| Product flyer PDF 264 kb |