From 18 - 23 September 2017, the leading international trade fair will once more offer a large number of recent innovations and official market launches.

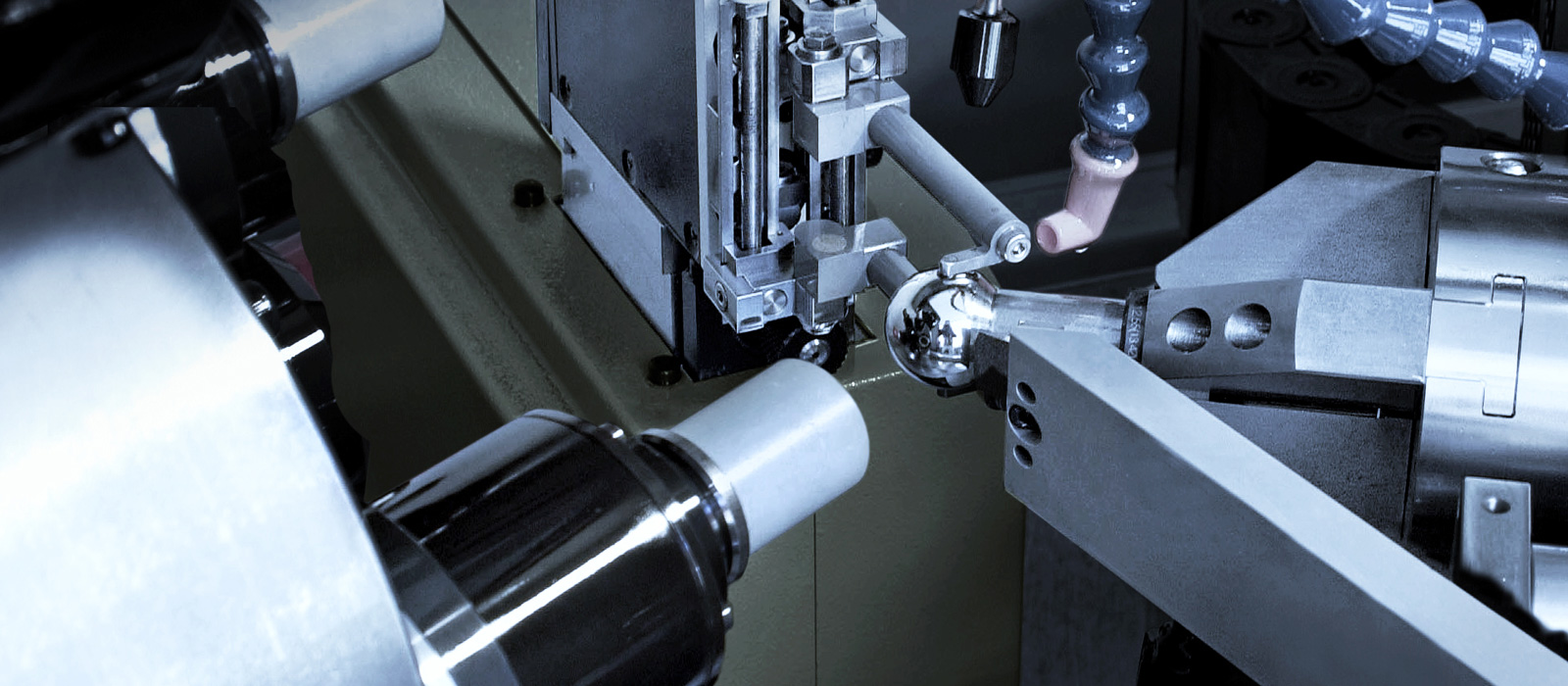

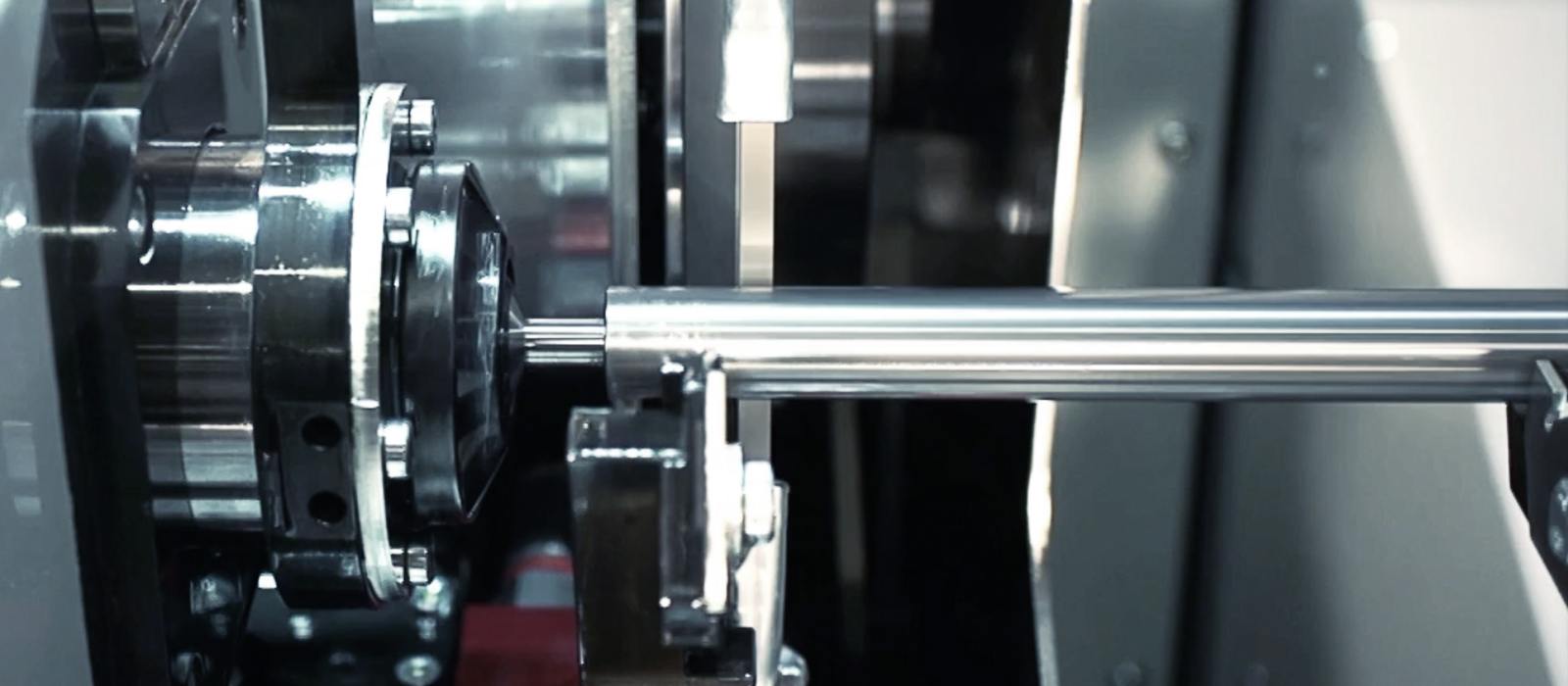

This year there will be a focus on medical technology. Both super abrasives and conventional grinding and polishing tools for finishing orthopaedic components as well as for medical instruments, injection needles and for dentistry.

In addition, two new product highlights will be presented for the first time on the TYROLIT stand - the COOL CUT 2 (for the knife industry) and the STARTEC PG-2 (for the tooling industry).

Hall 11, Stand C06