PREMIUM LONGLIFE cut-off wheels

for steel

Particularly durable high-performance tool for cutting steel plates, profiles, pipes, rods and solid material. Suitable for all common angle grinders. The PREMIUM LONGLIFE cut-off wheel for the angle grinder has been specially developed for long-lasting cutting applications. With its powerful design, it is the ideal tool for cutting steel and stainless steel. Made from extra high quality materials, it has been optimized for extra durability. Get the job done efficiently with this unique cut-off wheel. Show more Show less

- Maximum lifetime thanks to LONGLIFE technology

- Extremely short working times thanks to excellent cutting ability and a low thermal load on the workpiece (heat build-up)

- No reworking, such as cleaning or deburring, required

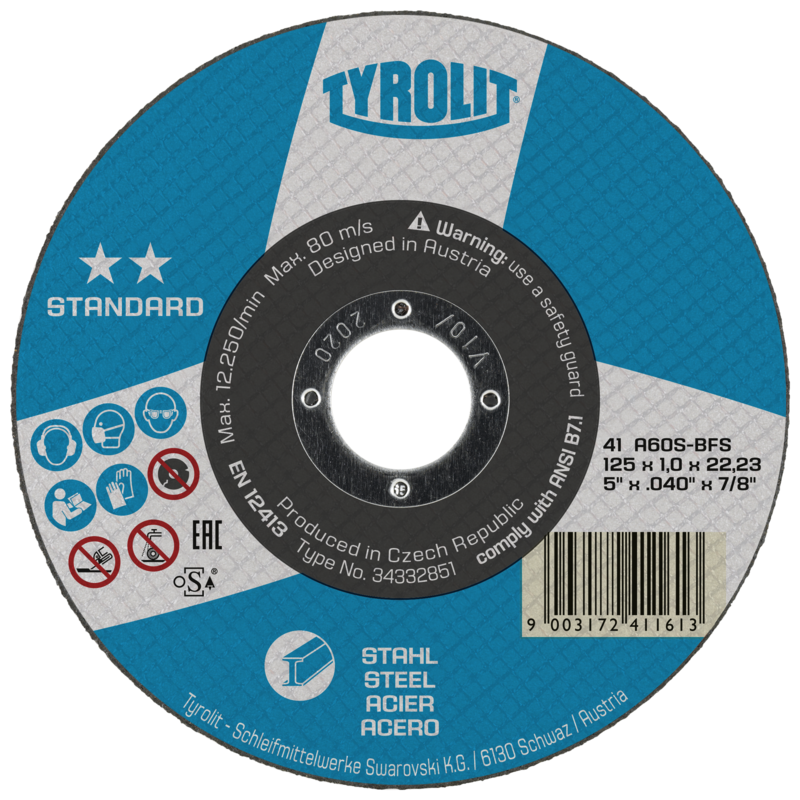

STANDARD cut-off wheels

for steel

Efficient tool for cutting metal plates, profiles, pipes, rods and solid material made of steel. Suitable for all common angle grinders. This STANDARD cut-off wheel offers operators an economical solution for cutting a wide range of steel moulds. It is a comfortable to use product for your daily challenges, not least because of the low thermal load on the workpiece. In any case, the STANDARD cut-off wheel is a good choice for efficient cutting of steel materials. Show more Show less

- Convenient cutting with excellent lifetime

- Short working times thanks to very good cutting ability and a low thermal load on the workpiece (heat build-up)

- No reworking, such as cleaning or deburring, required

PREMIUM CERABOND X Cut-off wheels

for steel and stainless steel

Highly efficient tool for cutting very hard workpieces of steel and stainless steel. Suitable for all common angle grinders. The PREMIUM CERABOND X cut-off wheel is your reliable partner for cutting very hard materials as well as workpieces with large cross-sections. The combination of a unique bond system with a self-sharpening ceramic grain achieves a particularly high cutting ability as well as a long tool life and at the same time prevents premature breaking out of the grain. Thus, with the CERABOND X tools, you are ideally equipped for any challenge. Show more Show less

- Shortest cutting times due to the structure of the ceramic grain used

- Very long lifetime on hard and demanding materials

- Extremely sharp cut-off wheel enables the user to work very comfortably and with little effort

PREMIUM CERABOND cut-off wheels

for steel and stainless steel

The CERABOND bond system developed by Tyrolit combines an easy cutting ceramic grain with a unique bond structure. This prevents premature break-out of the grain and increases the abrasiveness many times over. The CERABOND cut-off wheel range is particularly suitable for optimum machining of extremely hard, sophisticated workpieces and solid materials. The range stands for a long lifetime and shorter working processes with maximum economic efficiency. Through the introduction of the 1.0 mm cut-off wheel with CERABOND system, the product family has been extended by a powerful member. The CERABOND product line has thus been completed and is now available in the specialist retail worldwide Show more Show less

- Shorter working processes

- Improved productivity

- Lower production costs

PREMIUM 2-in-1 cut-off wheels

for steel and stainless steel

Highest performance tools for cutting steel and stainless steel. Suitable for all common angle grinders. The PREMIUM 2in1 cut-off wheel for the angle grinder is the perfect tool for a wide range of cutting applications. With its powerful design and high chemical purity, this tool is the ideal choice for cutting steel and stainless steel. Made from high-quality materials, this cut-off wheel offers excellent durability and longevity. Get the job done quickly and efficiently with this unique cut-off wheel. Show more Show less

- The chemical purity of the product prevents corrosion, pitting corrosion and reduction in fatigue strength for the best results even on stainless steel

- Extremely short working times thanks to excellent cutting ability and a low thermal load on the workpiece (heat build-up)

- High level of comfort thanks to easy-cutting specification

PREMIUM CERABOND X cut-off wheels

for cast iron

High performance tool for cutting various cast materials. Suitable for all common angle grinders. The well-known CERABOND X cut-off wheel from Tyrolit has now been specially adapted and optimized for cutting a wide variety of cast materials, such as spheroidal cast iron or cast iron with lamellar graphite. The new bond system efficiently prevents premature grain break-out, allowing you to achieve an incredible lifetime on cast materials with CERABOND X cut-off wheels. Due to the use of high-quality ceramic abrasive grains, you are guaranteed maximum aggressiveness throughout the lifetime. The high cutting ability of the cut-off wheels allows the operator to work very comfortably with little effort, which makes working with cast iron much easier. Particularly clean and bright cutting areas reduce rework and working hours, thus supporting the most economical work processes. Show more Show less

- Excellent lifetime and stability

- Cleanest surfaces without any discolouration reduce rework and working times

- Shortest cutting times and comfortable working with low effort

- Highest aggressiveness over the entire lifetime

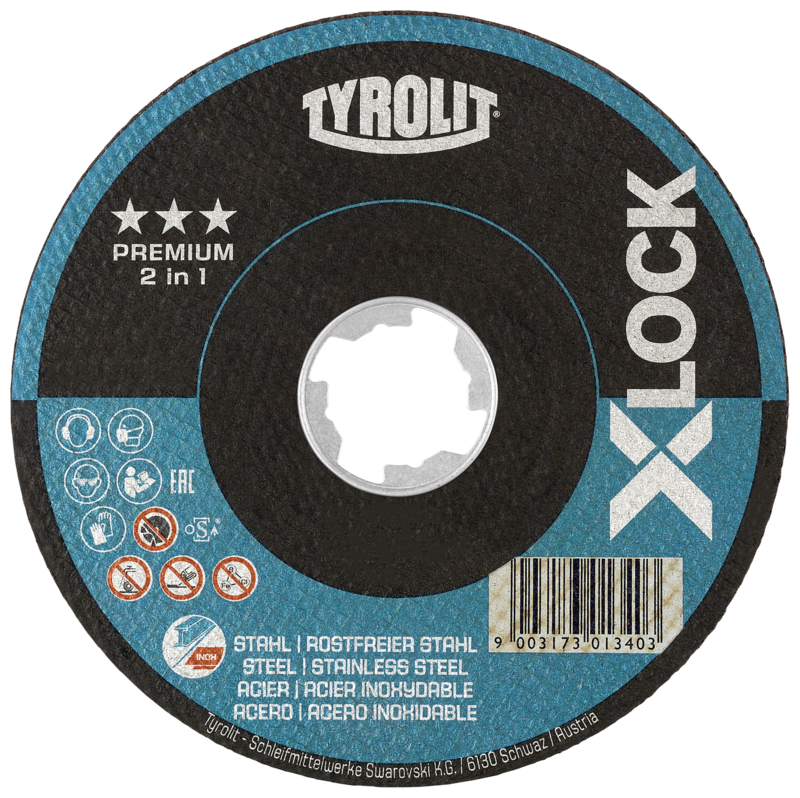

PREMIUM X-LOCK cut-off wheels

for steel and stainless steel

Highest performance tools with X-LOCK clamping system for cutting metal sheets, profiles, pipes, rods and solid materials made of steel and stainless steel. For angle grinders with X-LOCK clamping system. With the PREMIUM X-LOCK cut-off wheel for the angle grinder, the wheel change succeeds in no time. This tool has been specially designed for angle grinders with the X-LOCK clamping system and is perfect for cutting metal sheets, profiles, pipes, bars and solid material made of steel and stainless steel. It is designed to last long while providing excellent cutting results. Show more Show less

- Tyrolit integrates X-LOCK, the new clamping system from BOSCH, for a wide assortment of cut-off wheels, roughing wheels and flap discs

- The product offers easy handling and the highest safety

- No loose parts

PREMIUM DEEP CUT PROTECTION cut-off wheels

for steel and stainless steel

Highest performance tools with increased user safety for machining of metal plates, profiles, pipes, rods and solid material made of steel and stainless steel. Suitable for all common angle grinders. The PREMIUM DEEP CUT PROTECTION cut-off wheel takes another important step towards increased safety. A special metal bushing prevents the bore from breaking out, even when plunged to the maximum into the workpiece or in contact with sharp edges. This wheel thus meets any cutting challenge. Show more Show less

- The metal bushing with DEEP CUT PROTECTION prevents bore breakout

- Maximum insertion depths into the workpiece and contact with sharp workpiece edges possible without damaging the wheel

- DEEP CUT PROTECTION is a further step towards operator safety

- High level of comfort thanks to easy-cutting specification

PREMIUM ACCU cut-off wheels

for steel and stainless steel

Specially designed tool for cutting with a battery-powered angle grinder. Suitable for all common angle grinders. The PREMIUM ACCU cut-off wheel was specially developed for the cordless angle grinder and is ideal for cutting smaller diameters and bars. Cutting work can be performed quickly and with high working comfort even in hard-to-reach places. This cut-off wheel is the perfect accessory for any do-it-yourselfer or professional looking to take their cutting work to the next level. Show more Show less

- Work on smaller tasks in hard-to-reach areas without the need for a power source, while still benefiting from the usual Tyrolit quality

- Tool can be used for a wide variety of applications on steel and stainless steel

- Also makes light work of small cross-sections, rods and reinforced steel

PREMIUM CUT AND GRIND

for steel and stainless steel

Universal tool for cutting and grinding with Deep-Cut Protection. Suitable for all common angle grinders. The PREMIUM CUT AND GRIND cut-off wheel is a perfect universal tool for cutting and grinding. The cut-off wheel, which is made of high-quality materials, has a special deep cut protection and thus ensures maximum safety during cutting. With the CUT AND GRIND you can handle applications such as grinding and deburring as well as cutting and plunge in just one step. Show more Show less

- Thanks to CUT AND GRIND, applications such as grinding, deburring and shaping as well as cutting and plunging are possible with only one tool

- Thinner width of 2.0 mm with DEEP CUT PROTECTION offers additional safety for the operator and prevents bore breakout in the event of contact with sharp-edged workpieces

- Optimal cutting

STANDARD 2-in-1 cut-off wheels

for steel and stainless steel

Efficient tool for cutting metal sheets, profiles, pipes, rods and solid material made of steel and stainless steel. Suitable for all common angle grinders. STANDARD 2in1 cut-off wheel for angle grinder is the solution for those who are looking for a powerful tool for cutting metal sheets, profiles, pipes, bars and solid materials made of steel and stainless steel. It allows you to work comfortably, provides precise and reliable results and is designed for a long lifetime. This cut-off wheel is the perfect choice for those who want to tackle cutting jobs with maximum efficiency. Show more Show less

- The product offers very good lifetime and stability

- Quick and convenient to use

- Environmentally-friendly

STANDARD 2-in-1 cut-off wheels

for steel and stainless steel

Efficient tool for cutting metal sheets, profiles, pipes, rods and solid material made of steel and stainless steel. Suitable for all common angle grinders. The STANDARD 2in1 cut-off wheel, in the practical advantage box of 10 or 50 pieces, is the solution for those looking for a powerful tool for cutting metal sheets, profiles, pipes, bars and solid material made of steel and stainless steel. It allows you to work comfortably, provides precise and reliable results and is designed for a long lifetime. This cut-off wheel is the perfect choice for those who want to tackle cutting jobs with maximum efficiency. Show more Show less

- The product offers very good lifetime and stability

- Quick and convenient to use

- Environmentally-friendly

STANDARD 2-in-1 cut-off wheels

for steel and stainless steel

Efficient tool for cutting metal sheets, profiles, pipes, rods and solid material made of steel and stainless steel. Suitable for all common angle grinders. The STANDARD 2in1 cut-off wheel, in a cost-effective 100-piece stock bucket, is the solution for anyone looking for a powerful tool for cutting steel and stainless steel sheets, profiles, pipes, bars and solid material. It allows you to work comfortably, provides precise and reliable results and is designed for a long lifetime. This cut-off wheel is the perfect choice for those who want to tackle cutting jobs with maximum efficiency. Show more Show less

- The product offers very good lifetime and stability

- Quick and convenient to use

- Environmentally-friendly

BASIC CUT AND GRIND

for steel and stainless steel

Universal tool for cutting and grinding. Suitable for all common angle grinders. The BASIC CUT AND GRIND cut-off wheel is a universal tool for all cutting and grinding requirements. This cut-off wheel is designed to cut and grind quickly and efficiently with the angle grinder. With the CUT AND GRIND cut-off wheel, it is possible to handle applications such as grinding, deburring and shaping, as well as cutting and plunge in with just one tool and in one step. Show more Show less

- Thanks to CUT AND GRIND, applications such as grinding, deburring and shaping as well as cutting and plunging are possible with only one tool

- The product offers good performance with the highest safety standards

- Reduced working times

BASIC CUT-ALL cut-off wheels

for universal use

Universal tool for cutting a wide range of materials. Suitable for all common angle grinders. The new BASIC CUT-ALL cut-off wheel is a true all-rounder for all cutting tasks. Whether you want to cut steel, stainless steel, NF metals, PVC or even stone (e.g., concrete products, screed, sand-lime bricks, etc.), this tool is the smartest choice. Your wheel changes are reduced and you can still benefit from smooth running and low burr formation. The special composition prevents clogging of the wheel, even on aluminium and other NF metals. Our BASIC CUT-ALL is the right cut-off wheel for anyone who wants to save time without compromising on quality. Show more Show less

- Universal use on numerous materials

- Smooth cutting

- Low burr formation

BASIC 2-in-1 cut-off wheels

for steel and stainless steel

Tool for cutting sheets, profiles, pipes, rods and solid material made of steel and stainless steel. Suitable for all common angle grinders. The BASIC 2in1 cut-off wheel is the perfect tool for all cutting tasks. No matter if metal sheets, profiles, pipes, bars or solid material made of steel or stainless steel, with this cut-off wheel you are perfectly served. Rugged construction and reliable performance make this tool the perfect choice for do-it-yourselfer and professional alike. Get your cut-off jobs done faster and more efficiently with the BASIC 2in1 cut-off wheel. Show more Show less

- The chemical purity makes it possible to work on steel and stainless steel

- Convenient and low-burr cutting with good wheel life

- Short working times thanks to good cutting ability

BASIC 2-in-1 cut-off wheels

for steel and stainless steel

Tool for cutting metal sheets, profiles, pipes, rods and solid material made of steel and stainless steel. Suitable for all common angle grinders. The BASIC 2in1 cut-off wheel, in a convenient value box of 10, is the perfect tool for all cutting tasks. Whether it's metal sheets, profiles, pipes, bars or solid material made of steel or stainless steel, this cut-off wheel has you covered. Rugged construction and reliable performance make this tool the perfect choice for do-it-yourselfer and professional alike. Get your cut-off jobs done faster and more efficiently with the BASIC 2in1 cut-off wheel. Show more Show less

- The chemical purity makes it possible to work on steel and stainless steel

- Convenient and low-burr cutting with good wheel life

- Short working times thanks to good cutting ability

BASIC 2-in-1 cut-off wheels

for steel and stainless steel

Tools for cutting metal sheets, profiles, pipes, rods and solid material made of steel and stainless steel. Suitable for all common angle grinders. The BASIC 2in1 cut-off wheel, in the cost-effective stock bucket of 100 pieces, is the perfect tool for all cutting tasks. Whether metal sheets, profiles, pipes, bars or solid material made of steel or stainless steel, this cut-off wheel will serve you well. Rugged construction and reliable performance make this tool the perfect choice for do-it-yourselfer and professional alike. Get your cut-off jobs done faster and more efficiently with the BASIC 2in1 cut-off wheel. Show more Show less

- The chemical purity makes it possible to work on steel and stainless steel

- Convenient and low-burr cutting with good wheel life

- Short working times thanks to good cutting ability

STANDARD cut-off wheels

for stainless steel

Efficient tool for cutting stainless steel sheets, profiles, pipes, rods and solid material. Suitable for all common angle grinders. This STANDARD cut-off wheel for the angle grinder is an economical solution for the operator for several reasons. Thanks to its particularly high chemical purity, the disc is ideal for machining various grades of stainless steel, but of course it can also be used on steel. In addition, it is comfortable to handle and offers a good standing time as well as easy cutting ability. Show more Show less

- The chemical purity of the product prevents corrosion, pitting corrosion and reduction in fatigue strength for very good results on stainless steel

- Convenient cutting with excellent lifetime

- Short working times thanks to very good cutting ability and a low thermal load on the workpiece (heat build-up)

BASIC cut-off wheels

for stainless steel

Universal tool for cutting metal sheets, profiles, pipes, rods and solid material made of stainless steel. Suitable for all common angle grinders. The BASIC cut-off wheel for the angle grinder will take your work projects to the next level. This universal tool is perfect for cutting stainless steel sheets, profiles, pipes, bars and solid material. The BASIC cut-off wheel provides a precise cut every time so you can get the job done quickly and efficiently. Show more Show less

- The chemical purity of the product prevents corrosion, pitting corrosion and reduction in fatigue strength for good results on stainless steel

- Convenient and low-burr cutting with good wheel life

- The thickness of just 1.0 mm enables speed and precision when working

Cut-off wheels

for steel

Universal cut-off wheel for machining steel. Suitable for all common angle grinders. For universal use on steel, these cut-off wheels offer the perfect combination of lifetime and ease of use. These discs are specially designed for heavy cutting work on ferrous metals, such as steel, and should not be missing in any toolbox. Show more Show less

- Perfect combination of lifetime and ease of use

- For heavy cutting work

Cut-off wheels

for stainless steel

Cut-off wheel for machining low and high-alloyed stainless steel materials, plates and metal sheets. Suitable for all common angle grinders. Cut-off wheels specially designed for application on stainless steel, offering you an extended wheel life combined with a cool cutting performance. These discs are an essential tool for all operators who place high value on ease of use throughout the lifetime of the wheel. Show more Show less

- Long tool life

- Cool cutting performance

- User friendliness

Cut-off wheels

for stone

Specially designed cut-off wheel for machining marble, natural or artificial stone. Suitable for all common angle grinders. The cut-off wheels have been specially developed for application on stone and offer you high aggressiveness coupled with a long tool life. This is achieved by using high-quality silicon carbide grain. Further advantages for the operator are the cool grinding performance and the high usability of the wheels. Show more Show less

- Ease of use

- Long tool life due to cool cutting performance

- High aggressiveness

Cut-off wheels

for cast iron

Specially designed cut-off wheel for the machining of cast iron. Suitable for all common angle grinders. The cut-off wheels have been specially developed for application on cast iron and are characterized by an optimum balance of operator friendliness and lifetime. This is not least due to the specially developed mixture of aluminum oxide and silicon carbide grains. This tool is particularly suitable for machining ductile iron pipes and other soft metals. Show more Show less

- Balance of lifetime and user friendliness

- Special grain mixture

- High aggressiveness

BASIC cut-off wheels

for stainless steel

Universal tool for cutting metal sheets, profiles, pipes, rods and solid material made of stainless steel. Suitable for all common angle grinders. The BASIC cut-off wheel, in a convenient value box of 10, will take your work projects to the next level. This universal tool is perfect for cutting stainless steel sheets, profiles, pipes, bars and solid material. The BASIC cut-off wheel provides a precise cut every time, so you can get the job done quickly and efficiently. Show more Show less

- The chemical purity of the product prevents corrosion, pitting corrosion and reduction in fatigue strength for good results on stainless steel

- Convenient and low-burr cutting with good wheel life

- The thickness of just 1.0 mm enables speed and precision when working

PREMIUM cut-off wheels

for nonferrous metals

Specially developed highest performance tools for cutting nonferrous metals. Suitable for all common angle grinders. The PREMIUM cut-off wheel for the angle grinder is a highest performance tool that makes cutting nonferrous metals a breeze. Designed specifically for materials like aluminium, it delivers a smooth, professional cut with minimal effort. New specifications prevent clogging and dulling from material abrasion, making it extra long lasting with consistent performance. Show more Show less

- New specifications prevent clogging and dulling of the wheel

- Specification and manufacturing method enable the shortest cutting times

- Enhanced performance

PREMIUM cut-off wheels

for nonferrous metals and stone

Highest performance tools for machining nonferrous metals and stones. Suitable for all common angle grinders. This PREMIUM cut-off wheel enables power-reduced work on a wide range of materials. Whether tiles, ceramics, bricks or nonferrous metals - a clean cut with minimal effort is guaranteed with this tool. In addition, the low wheel thickness of just one millimeter ensures reduced formation of dust during cutting as well as little cutting waste - a plus in terms of operator and environmental friendliness. Show more Show less

- Perfect surface finish without any edge chipping

- Reduced cutting waste and cutting dust generation thanks to small wheel thickness

- Low load

STANDARD cut-off wheels

for stone

Efficient tool for cutting stone. Suitable for all common angle grinders. With this STANDARD cut-off wheel you can cut a wide variety of stone types without any problems and without major exertion - be it tiles, ceramics, bricks and sometimes concrete. The result is consistently clean cutting edges. Due to the silicon carbide grain used, you can be sure of a very good standing time and high stability during cutting. Show more Show less

- Clean cutting edges and very good cutting quality

- Fast and convenient work with minimal exertion

- Silicon carbide ensures very good lifetime and stability when cutting stone and concrete

BASIC cut-off wheels

for stone

Tool for cutting stone. Suitable for all common angle grinders. This BASIC cut-off wheel is suitable for cutting a wide variety of stone materials, including tiles, ceramics as well as bricks. Available in thicknesses between 2.5 and 3 mm, these tools allow for clean cutting edges. The BASIC cut-off wheel thus offers you a cost-effective option for stone cutting requirements. Show more Show less

- Good cutting ability reduces the operator's work

- Quick and convenient to use

- Good lifetime and stability

PREMIUM FOCUR SA cut-off wheels

for grey and spheriodal cast iron

Specially developed highest performance tools for cutting gray and spheroidal cast iron. Suitable for all common 230mm angle grinders. The PREMIUM FOCUR SA is a diamond cut-off wheel and your ideal partner for machining gray and spheroidal cast iron. Compared to ordinary resin cut-off wheels, this tool offers up to 25 times longer standing time. Benefit from the exceptional aggressiveness of this wheel, which is achieved not least through the use of diamond grit. Show more Show less

- DIN 13236 safety norm

- Highest aggressiveness with unbelievable lifetime thanks to an innovative production technology and the use of diamond grains

- Up to 25 times higher lifetime compared to vitrified bonded tools

| Downloads |

|---|

| Product flyer PDF 305 kb |

PREMIUM cut-off wheels

for cast iron

Highest performance tools for machining various cast materials. Suitable for all common 230mm angle grinders. The PREMIUM cut-off wheel was specially developed for comfortable work on all cast materials. Thanks to an innovative manufacturing technology combined with the use of a high quality zirconium aluminium oxide, this tool has an exceptional cutting ability. The cut-off wheel is available in 3 different hardnesses - so you are well equipped for any application on castings. Show more Show less

- Highest aggressiveness thanks to innovative production technology

- New bond system combined with high-quality zircon corundum enables shortest cut-off times

- Maximum comfort when machining the hardest workpieces

- Best lifetime for economical work

Wheel flange - accessory

for cut-off wheels

High quality accessories for increasing lateral stability of cut-off wheels with 178 and 230 mm diameter. Suitable for all common angle grinders. With the PREMIUM collet, you increase lateral stability many times over when working with cut-off wheels and benefit from more precise cutting. Made of quenched and tempered tool steel, this accessory is suitable for all cut-off wheels with a diameter of 178 and 230 mm and a thickness of up to 2 mm. Show more Show less

- Significantly increases lateral stability

- Made of tempered tool steel for angle grinders with an M14 drive screw

- Enables even more precise cutting guidance and improves first-cut performance

PREMIUM cut-off wheels

for stainless steel

Highest performance tools for cutting metal plates, profiles, pipes, rods and solid material made of stainless steel. Suitable for all common angle grinders. The PREMIUM cut-off wheel for the angle grinder is the tool you've always been looking for. With a particularly high chemical purity, this cut-off wheel is perfect for cutting metal sheets, profiles, pipes, bars and solid material made of stainless steel. It's designed to last while delivering excellent cutting results. Get ready to take your projects to the next level with this cut-off wheel. Show more Show less

- The chemical purity of the product prevents corrosion, pitting corrosion and reduction in fatigue strength for the best results on stainless steel

- Extremely short working times thanks to excellent cutting ability and a low thermal load on the workpiece (heat build-up)

- Specially for rust-resistant and acid-resistant steels

PREMIUM cut-off wheels

for stainless steel

Highest performance tools for cutting metal plates, profiles, pipes, rods and solid material made of stainless steel. Suitable for all common angle grinders. The PREMIUM cut-off wheel, in a convenient value box of 10, is the tool you've always been looking for. With a particularly high chemical purity, this cut-off wheel is perfect for cutting stainless steel sheets, profiles, pipes, bars and solid material. It's designed to last while delivering excellent cutting results. Get ready to take your projects to the next level with this cut-off wheel. Show more Show less

- The chemical purity of the product prevents corrosion, pitting corrosion and reduction in fatigue strength for the best results on stainless steel

- Extremely short working times thanks to excellent cutting ability and a low thermal load on the workpiece (heat build-up)

- Specially for rust-resistant and acid-resistant steels